CNC machining has transformed the way products are designed and manufactured. From aerospace components to custom automotive parts, this technology is at the heart of modern engineering. In the UK, CNC machining plays a crucial role in keeping industries competitive, efficient and innovative.

If you’re looking to understand the CNC machining UK environment, whether as a buyer, engineer or manufacturing enthusiast, this guide covers everything from the basics to the benefits, applications and future trends.

What Is CNC Machining?

CNC stands for Computer Numerical Control – a manufacturing process where pre-programmed computer software dictates the movement of machinery and tools. It allows manufacturers to produce precise, complex parts with minimal manual intervention.

Instead of relying on hand-operated machinery, CNC machining uses digital instructions, often derived from CAD (Computer-Aided Design) models to create parts that meet exact specifications.

Key features of CNC machining:

High precision and repeatability

Ability to create complex shapes and contours

Wide material compatibility (metals, plastics, composites and more)

Scalability from prototypes to large production runs

How CNC Machining Works

The CNC process involves several key steps:

1. Design & CAD Modelling

Engineers create a digital 3D model of the part using CAD software.

2. CAM Programming

The model is translated into machine instructions using CAM (Computer-Aided Manufacturing) software.

3. Machine Setup

The CNC machine is prepared with the correct tools, fixtures and materials.

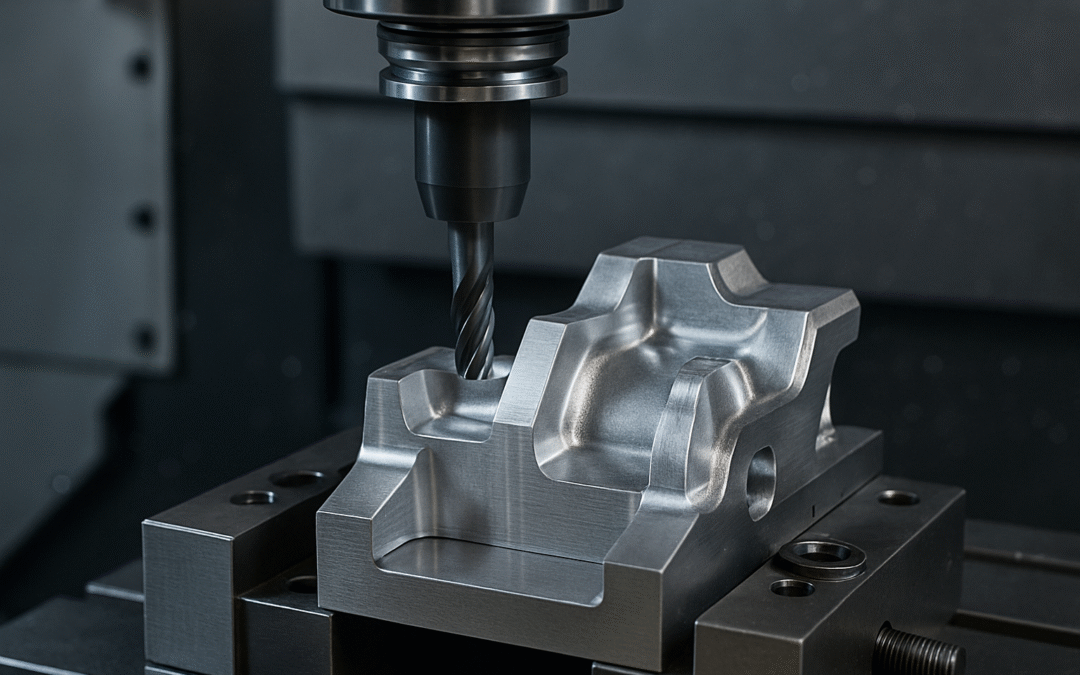

4. Automated Machining

The machine follows the programmed toolpaths to cut, mill, drill or turn the material.

5. Inspection & Quality Control

Finished parts undergo rigorous testing to ensure they meet specifications.

Types of CNC Machines

In the UK, manufacturers use a variety of CNC machines depending on the part complexity and production requirements.

CNC Milling Machines – Use rotating cutting tools to remove material from a workpiece.

CNC Lathes (Turning Machines) – Spin the material while cutting tools shape it.

CNC Routers – Ideal for wood, plastics and soft metals.

CNC Plasma Cutters – Use a plasma torch to cut metals.

CNC Laser Cutters – High precision cutting using focused laser beams.

CNC Grinding Machines – Achieve ultra-fine finishes and tight tolerances.

Multi-Axis CNC Machines – Allow complex machining from multiple angles in one setup.

Benefits of CNC Machining for UK Manufacturers

The UK’s manufacturing sector is constantly under pressure to improve productivity, reduce costs and maintain high standards. CNC machining offers clear advantages:

Unmatched Accuracy – Tolerances down to microns, ensuring parts fit perfectly.

Consistency – Every unit matches the original design, vital for large production runs.

Efficiency – Reduced setup time and faster production cycles.

Material Versatility – Works with aluminium, steel, titanium, plastics, and composites.

Reduced Waste – Precision cutting means less scrap material.

Lower Labour Costs – Fewer manual operations needed.

Faster Prototyping – Rapid transition from design to finished product.

CNC Machining Applications in the UK

CNC machining is used across a wide range of industries in the UK, including:

Aerospace – Engine parts, airframe components and landing gear systems.

Automotive – Engine blocks, gearboxes and custom performance parts.

Medical Devices – Surgical instruments, implants and diagnostic equipment.

Defence – Precision components for military vehicles and equipment.

Energy – Turbine blades, oil and gas components and renewable energy parts.

Marine – Propeller shafts, engine parts and navigation equipment.

Consumer Goods – Electronics, home appliances and bespoke products.

CNC Machining in the UK: Industry Standards & Quality

In the UK, precision manufacturing isn’t just about producing accurate parts, it’s about meeting recognised quality standards that ensure reliability, safety and long-term performance. Two important certifications in CNC machining UK are:

ISO 9001 – Quality Management Systems

This is the benchmark for consistent quality across manufacturing processes. It covers everything from supplier management and traceability to inspection procedures and customer satisfaction. For CNC machining, it means every stage, from CAD programming to final inspection, follows a structured, documented process.

AS9100 – Aerospace Manufacturing Standards

Built on ISO 9001, AS9100 adds rigorous requirements specifically for the aerospace sector. It demands exceptional traceability, precision and risk management. Even if you’re not in aerospace, working with an AS9100-certified company gives reassurance that the same meticulous processes apply to your project.

Tarvin Precision holds both ISO 9001 and AS9100 certifications, meaning our clients benefit from world-class quality management and aerospace-grade production standards. Every part we produce – whether for aerospace, automotive, or industrial use – is made under strict process control, detailed documentation, and rigorous inspection procedures to ensure unmatched accuracy and reliability.

The CNC Machining Process in Detail

While the basic steps are straightforward, let’s break down the UK CNC machining process in a little more detail.

1. Consultation & Design

Clients provide requirements, drawings, or CAD files. UK manufacturers often offer design assistance to ensure cost-effective production.

2. Programming

Specialists convert CAD designs into CNC code (often G-code), defining every movement of the cutting tools.

3. Material Selection

Choice of material depends on strength, weight, corrosion resistance and cost.

4. Prototyping

Small test runs are produced to check for fit, performance and manufacturability.

5. Full Production

Once the prototype is approved, production scales up, often running 24/7 for efficiency.

6. Inspection

Coordinate Measuring Machines (CMMs) and other inspection tools ensure every part meets the required tolerances.

Why Choose CNC Machining in the UK Instead of Overseas?

With global manufacturing options, some might wonder why choose a local UK CNC supplier. The advantages include:

Shorter Lead Times – Faster turnaround without shipping delays.

Better Communication – Direct access to engineers and project managers.

Quality Assurance – Compliance with UK and EU regulations.

Supporting Local Industry – Boosting UK manufacturing and jobs.

Reduced Carbon Footprint – Lower transportation emissions.

CNC Machining UK Costs: What to Expect

Pricing depends on several factors:

Material type and availability

Part complexity

Volume of production

Required tolerances

Additional finishing (anodising, powder coating, polishing, etc.)

While UK manufacturing might seem more expensive than overseas alternatives, the savings in lead time, quality and logistics often outweigh the price difference.

Future of CNC Machining in the UK

The UK is at the forefront of adopting advanced manufacturing technologies. Expect to see:

Automation & AI Integration – Predictive maintenance, process optimisation.

Hybrid Manufacturing – Combining CNC machining with additive manufacturing (3D printing).

Sustainable Practices – Recycling scrap materials, using eco-friendly coolants.

Advanced Materials – Machining composites, titanium alloys and other high-performance materials.

Choosing the Right CNC Machining Partner in the UK

When selecting a supplier, consider:

Experience in your industry

Range of CNC machinery and capabilities

Quality certifications

Lead times and scalability

Client reviews and case studies

Example Project: How a CNC Machining Partner Can Solve Tight-Deadline Challenges

To understand how CNC machining UK can help businesses, let’s look at a typical example scenario based on the kind of work Tarvin Precision regularly undertakes.

The Situation

Imagine a mid-sized UK automotive components manufacturer preparing to launch a new performance gearbox. They need 500 precision-machined aluminium housings – each with tight tolerances of ±0.01mm – and the project must be completed in just three weeks to align with their assembly schedule.

The Potential Challenges

Overseas suppliers could offer lower prices but with a six-week shipping lead time.

Some local suppliers might struggle to meet both the precision and volume requirements simultaneously.

The design features complex internal geometry, requiring both milling and turning operations.

How Tarvin Precision Might Approach It

Design Review – Our engineers could review CAD models and suggest small adjustments to improve machinability without affecting functionality.

Material Selection – We would source aerospace-grade aluminium from trusted UK suppliers to ensure consistency and quick turnaround.

Efficient Programming – Using 5-axis CNC machining, we could reduce the number of setups and speed up production.

Parallel Production – Running multiple machines simultaneously to meet volume demands.

Ongoing Quality Checks – Regular CMM inspections to maintain tolerance accuracy.

Expected Outcome in This Example

- The project could be completed ahead of schedule, allowing the client to meet their launch deadline.

- Tolerances would be consistently within the required specification.

The client would avoid shipping delays, reduce risk and support UK manufacturing.

CNC Machining UK: Driving Quality, Speed, and Innovation

CNC machining is the backbone of modern UK manufacturing. From precision aerospace components to one-off prototypes, the process delivers exceptional accuracy, speed and flexibility. Whether you’re a business seeking a reliable production partner or an engineer exploring manufacturing options, understanding CNC machining UK will help you make informed decisions that lead to better products, faster delivery and long-term success.