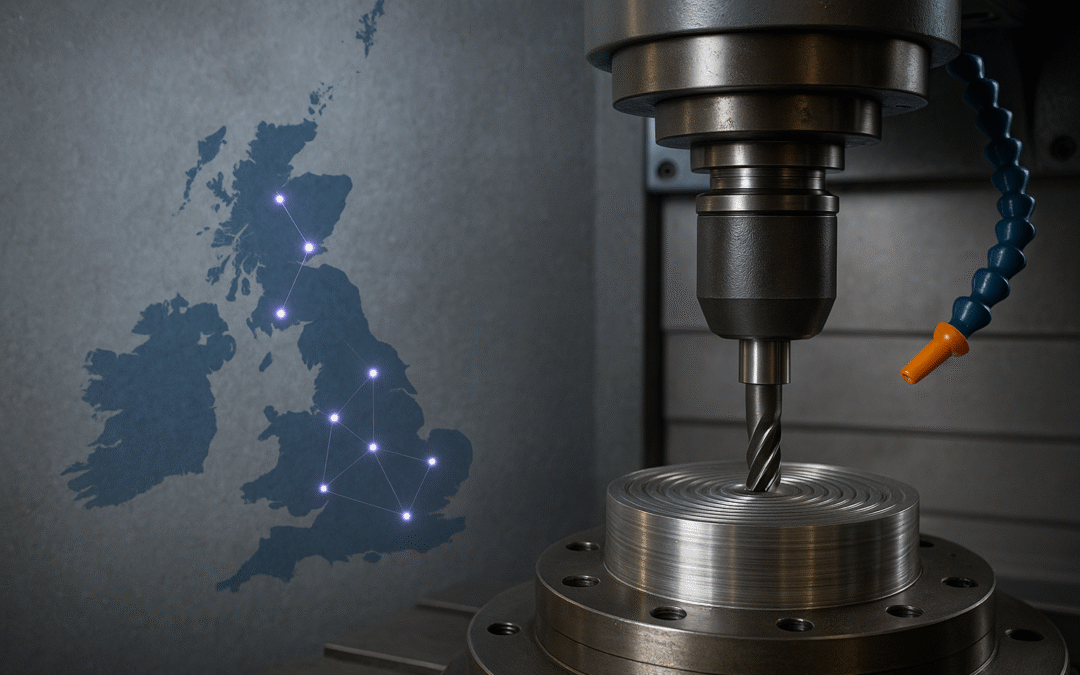

Precision engineering companies are one of the driving forces behind Britain’s industrial strength. Regional expertise, national supply chains and engineering innovation combine to maintain the country’s reputation for quality and performance.

Precision engineering companies form the foundation of Britain’s industrial capability. From the high-tech aerospace hubs of the North West to the scientific innovation of Cambridge, these firms ensure the nation’s manufacturing excellence continues to thrive.

Across every region of the UK, skilled engineers produce components that enable innovation in aerospace, automotive, energy, defence, and medical technology. Each area brings its own strengths, yet all share a dedication to accuracy, reliability, and performance.

At the centre of this network are subcontract precision engineering specialists who combine technical skill with responsiveness and quality assurance. Companies like Tarvin Precision, based in Flintshire, exemplify how British firms continue to deliver exceptional results for customers nationwide.

The Evolution of Precision Engineering in the UK

The history of UK precision engineering companies reveals how technology and craftsmanship evolved together, from post-war manufacturing to today’s digital machining and automation era.

The UK’s precision engineering sector has evolved through decades of industrial progress. After the Second World War, Britain’s reputation for mechanical and aerospace innovation created a demand for components with ever-tighter tolerances. By the 1980s and 1990s, CNC machining transformed production, allowing small and medium-sized workshops to achieve consistent, repeatable precision. Instead of mass production, the focus shifted to high-value, low-volume manufacturing where craftsmanship met technology.

Today, precision engineering companies are digitalised, data-driven, and quality-led. They support the nation’s most advanced sectors through continuous investment in 5-axis machining, CAD/CAM software, and inspection systems that guarantee traceability and compliance. This foundation enables UK regional manufacturing clusters to innovate confidently, knowing that local precision partners can deliver world-class components quickly and dependably.

Regional Centres of Precision Engineering Excellence in the UK

Across the UK, precision engineering companies form local ecosystems of innovation and skill. Each region specialises in key sectors – from aerospace and automotive to renewable energy and scientific research – demonstrating the diversity of British manufacturing excellence.

North West: Aerospace, Automotive, and Advanced Materials

The North West of England remains one of Britain’s strongest precision engineering regions. Manchester, Liverpool, and Cheshire host leading aerospace and automotive manufacturers alongside a network of subcontract CNC machining firms.

These precision engineering companies in the North West produce parts for aircraft systems, performance vehicles, and advanced material assemblies. Their expertise lies in machining aluminium, titanium, and high-temperature alloys with micron-level tolerances.

Firms such as Tarvin Precision play a vital role in this ecosystem, offering flexible capacity for milling, turning, and 5-axis machining, supported by ISO-certified quality systems. The region’s emphasis on innovation and lean operations ensures manufacturers can source critical components locally without compromising on quality or lead time.

Midlands: Britain’s Engineering Powerhouse

The Midlands remains synonymous with engineering innovation and technical manufacturing. Precision engineering companies in the Midlands support a wide range of industries from automotive and rail to advanced materials and energy systems.

Known as the heart of British engineering, the Midlands continues to be a hub for mechanical and precision manufacturing. Birmingham, Coventry, and Derby host world-renowned companies in the automotive, rail, and energy sectors.

Here, precision engineering companies in the Midlands provide everything from prototype machining and tooling to full production support. As electrification reshapes the automotive supply chain, regional subcontractors help OEMs adapt through component redesign, DFM consultation, and advanced machining processes.

Automation, robotics, and smart manufacturing are widely adopted across this region, driving efficiency while maintaining the craftsmanship that defines Midlands engineering.

Scotland: Offshore, Energy and Renewables Engineering

Scotland’s precision engineering companies continue to deliver excellence across energy and offshore industries. The transition from oil and gas to renewables has strengthened the country’s role in sustainable, high-precision manufacturing.

Scotland’s reputation for engineering excellence centres on Aberdeen and its surrounding offshore industry. For decades, precision engineering companies in Scotland have supported oil and gas operations with components designed to withstand extreme pressures, temperatures, and corrosion.

As the UK transitions to renewable energy, these same firms are applying their expertise to wind, hydrogen, and tidal energy systems, machining large and complex parts for subsea and onshore applications.

The ability to deliver precision under challenging conditions demonstrates why Scotland remains an essential contributor to the UK’s advanced manufacturing network.

South & South West: Defence, Marine, and Aerospace

From Bristol to Plymouth, the South and South West region showcases UK precision engineering companies that serve high-specification sectors including defence, marine, and aerospace. These firms combine legacy expertise with modern digital manufacturing.

Stretching from Bristol to Portsmouth and Plymouth, the South and South West form another vital precision manufacturing corridor. The region’s strong defence, aerospace, and marine sectors rely on a network of specialist subcontractors.

Precision engineering companies in the South West produce high-tolerance components for aircraft structures, propulsion systems, and naval hardware. Many collaborate directly with major primes such as BAE Systems and Airbus, maintaining strict confidentiality, traceability, and compliance with defence standards.

With the rise of hybrid manufacturing, additive and subtractive processes are now combined to improve strength and reduce waste, reinforcing the South West’s position as a centre for engineering innovation.

Wales: Expanding Advanced Manufacturing Hubs

The growth of precision engineering companies in Wales reflects a national effort to expand high-tech manufacturing. Welsh firms combine technical agility with academic and industry collaboration to serve global customers.

Wales has seen substantial investment in high-tech engineering, with clusters forming around Deeside, Cardiff, and North Wales. Aerospace, electronics, and energy technology are growing sectors supported by a community of skilled precision machinists.

Precision engineering companies in Wales are recognised for their agility, able to handle prototype work, low-volume runs, and specialist assemblies. Academic partnerships and government-backed innovation programmes have strengthened these SMEs’ ability to export precision components across Europe and beyond.

Wales’ combination of education, innovation, and engineering skill makes it one of the UK’s most promising manufacturing regions.

Northern Ireland:Precision and Export Excellence

Northern Ireland’s precision engineering sector demonstrates the country’s ability to compete globally. This section explores how precision engineering companies in Northern Ireland combine craftsmanship, certification, and export capability.

Northern Ireland’s manufacturing economy continues to punch above its weight. From aerospace and transport to medical devices, precision engineering companies in Northern Ireland are major exporters of high-value, small-batch components.

These firms maintain rigorous quality systems and often hold AS9100 and ISO 9001 certification, ensuring every component meets international standards. Close collaboration with mainland UK suppliers strengthens logistics and enables shared access to machining technologies and inspection resources.

The result is a region that excels in both craftsmanship and modern manufacturing performance.

Cambridge & the East: Scientific and Technological Innovation

The Cambridge region highlights how precision engineering companies in the East of England serve the UK’s scientific and medtech sectors. Their work supports innovation in research, instrumentation, and emerging technologies.

The Cambridge region, part of the UK’s “Golden Triangle” of innovation, showcases the other face of precision engineering, science and technology.

Here, precision engineering companies in Cambridge and the East of England support research organisations, laboratories, and med-tech firms with components for scientific instruments, optics, and diagnostic systems.

Machining these small, intricate parts demands ultra-clean processes, specialist materials, and precise dimensional control. Subcontract engineers often bridge the gap between design and production, turning R&D prototypes into commercial products.

This region demonstrates how precision engineering underpins not only heavy industry but also the UK’s most advanced scientific breakthroughs.

What Defines the Best Precision Engineering Companies

The UK’s most successful precision engineering companies share a set of qualities that ensure consistent excellence – technical expertise, certification, flexibility, and collaborative problem-solving.

Advanced Technical Capability

Leading UK precision engineering companies combine extensive machining capacity with deep process knowledge. Multi-axis CNC milling and turning, 5-axis machining, and complex assembly are standard offerings.

Digital CAD/CAM integration allows engineers to move seamlessly from model to manufacture, ensuring accuracy and repeatability on every batch.

Certified Quality and Inspection

Quality is non-negotiable. The best firms hold ISO 9001 or AS9100 certifications and maintain full traceability across materials and processes. Coordinate Measuring Machines (CMM), first-article inspection reports, and Certificates of Conformity ensure quality assurance confidence from prototype to production.

Design for Manufacture and Collaboration

Precision engineering thrives on partnership. Early DFM collaboration allows engineers to identify cost-saving adjustments without compromising function. This approach shortens lead times and improves manufacturability, vital for customers working under tight schedules.

Flexibility and Responsiveness

From one-off prototypes to repeat production, flexibility remains a defining strength of UK subcontract precision engineering. Many firms specialise in low-volume, high-variety work, adapting quickly to new designs and market requirements.

Partnership and Communication

True precision isn’t just dimensional, it’s operational. Transparent communication, on-time delivery, and technical feedback make the best precision engineering suppliers long-term partners rather than one-off vendors.

Subcontract Precision Engineering and the Connected UK Supply Chain

As subcontract precision engineering companies in the UK become more connected, they strengthen national manufacturing resilience. This section highlights how local specialists deliver flexibility and reduce supply-chain risk.

The UK’s supply chain depends on collaboration between regional specialists. Subcontract precision engineering companies provide the capacity and expertise that allow OEMs to scale, diversify, and innovate.

Sourcing components from within the UK offers significant benefits:

- Faster lead times and reduced logistics costs.

- Lower carbon footprint through shorter transport routes.

- Easier communication and agile design iteration.

- Compliance with British quality and traceability standards.

From a central base in the North West, companies like Tarvin Precision support customers across the country, contributing to a truly connected network of British engineering excellence.

Future Trends Shaping UK Precision Engineering

The future of precision engineering in the UK is being shaped by automation, sustainability, and innovation across emerging sectors such as EVs, renewables, and med-tech.

Digital Manufacturing and Automation

Smart machining, real-time data analysis, and predictive maintenance are transforming workshops into connected digital environments. Automation enhances consistency and frees skilled machinists to focus on complex setups and process optimisation.

Sustainability and Material Efficiency

Modern precision engineering UK providers are investing in sustainability, reducing waste, recycling metal swarf and optimising energy use. Eco-efficient practices are now part of competitiveness and compliance.

Skills and Workforce Development

Apprenticeships and continuous training remain vital. The UK’s engineering workforce combines generational expertise with fresh digital skills, ensuring the sector can adapt to new materials, controls, and markets.

Emerging Sectors Driving Demand

The rise of electric vehicles, green energy, medical technology and space manufacturing is creating new opportunities for precision engineers. Each relies on accuracy, reliability, and innovation – qualities that define British manufacturing.

Precision Engineering: Strength in Every Region

The UK’s precision engineering companies embody regional pride and national capability. Together, they form a network that powers every sector of modern manufacturing.

From the industrial heartlands of Manchester and Birmingham to the scientific corridors of Cambridge and the offshore expertise of Aberdeen, Britain’s precision engineering companies represent the backbone of modern manufacturing.

Each region contributes something unique: innovation, craftsmanship, or specialised industry knowledge. Together, they form a resilient and connected network capable of meeting the most demanding challenges.

Whether your project involves aerospace assemblies, energy systems, or scientific equipment, you can depend on the expertise of UK precision engineers. At Tarvin Precision we deliver precision at every step, ensuring quality, reliability and performance. We are proud to play our part in the story of keeping Britain’s manufacturing future strong.