Reverse Engineered Parts: A Practical Guide to Replacement Components and Legacy Hardware

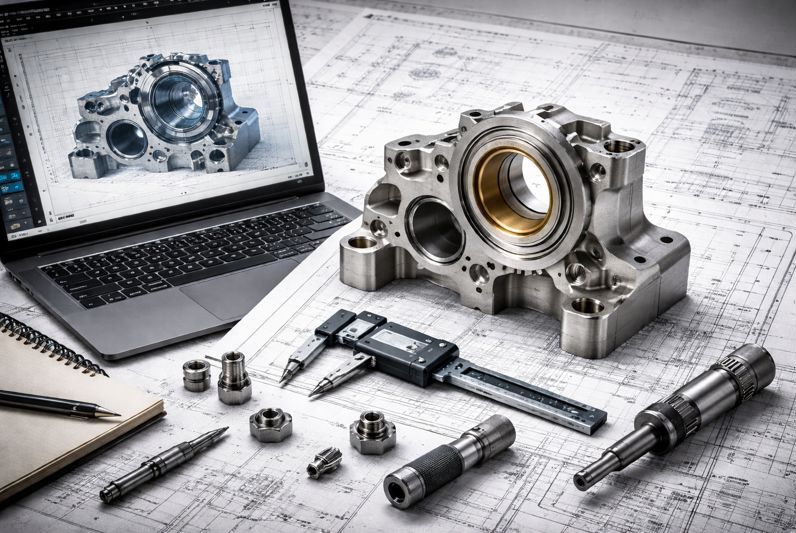

Reverse engineered parts are components recreated by capturing the geometry, material intent, and functional requirements of an existing item - often when drawings are missing, suppliers have vanished, or equipment has been modified over time. Done well, reverse...

CNC Components: A Practical Guide to Design, Materials, Tolerances and Manufacturing

CNC components sit quietly behind a huge amount of modern engineering - inside analytical instruments, automation cells, medical devices, aircraft subassemblies, energy systems, and high-end consumer products. The reason is straightforward: CNC machining offers a...

CNC Machining Costs: A Practical Guide to What You’ll Pay

CNC machining costs can feel mysterious because the final price is the sum of lots of small decisions: geometry, material, tolerances, setup time, programming effort, inspection requirements, finishing, and the simple reality of how long the machine is cutting metal...

Component Manufacturers: How to Choose, Specify and Scale Quality Parts

Component manufacturers sit at the quiet centre of almost every product you can name - from industrial sensors and medical devices to aerospace subsystems and energy infrastructure. When they perform well, your production line runs smoothly, your field returns stay...

A Refreshed Look for Our Vans and Another Win for Local Welsh Suppliers

Our delivery vans have been part of the day-to-day for some time now, so it felt like the right moment to update their appearance. We’ve just had a new set of graphics applied and we’re genuinely delighted with the result - clean, sharp, and properly finished. What...

CNC Brass Parts: A Practical Guide to Materials, Design, Tolerances, Finishing, and Cost

CNC brass parts are everywhere once you start looking: electrical terminals, valves, pneumatic fittings, knobs, threaded inserts, instrument components, decorative hardware, and countless “small but critical” pieces that keep assemblies working. Brass machines well,...

Medical CNC Machining: A Complete Guide to Precision Parts for Healthcare

Medical CNC machining sits at the intersection of advanced manufacturing and patient safety. From surgical instruments and diagnostic device components to precision housings and orthopedic hardware, CNC (computer numerical control) machining helps produce complex...

Machining Magnesium: A Practical Guide to Safe, Accurate, High-performance Parts

Machining magnesium can feel like a cheat code when you need lightweight parts with excellent machinability. Magnesium alloys are among the easiest structural metals to cut, often allowing high material removal rates, good surface finish, and shorter cycle times...

Machined Plastic Parts: A Practical Guide to Materials, Design, Quality and Performance

Machined plastic parts sit in a useful middle ground between metal components, injection moulded plastics, and additive manufacturing. They can be produced quickly from engineering-grade polymers, hold tight tolerances when designed sensibly, and offer material...

Medical Component Manufacturers: How to Choose the Right Partner for Precision, Compliance, and Scale

Medical component manufacturers sit at the intersection of engineering, traceability, and patient safety. Whether you’re developing a new diagnostic device, an instrument assembly, a fluid-handling module, or a precision subcomponent for a regulated product, the...

What is AS9100? The Aerospace Quality Standard Explained for CNC Machining & Assembly

What is AS9100? AS9100 is the quality management system (QMS) standard used across the aviation, space and defence supply chain. It builds on ISO 9001 and adds aerospace-specific requirements that help organisations control risk, manage configuration (revision...