CNC machining has become the backbone of modern precision engineering, providing manufacturers across the UK with the ability to deliver highly accurate, repeatable, and efficient production. From aerospace and defence to scientific instrumentation and automotive, companies depend on the versatility of CNC machining to transform raw materials into critical components.

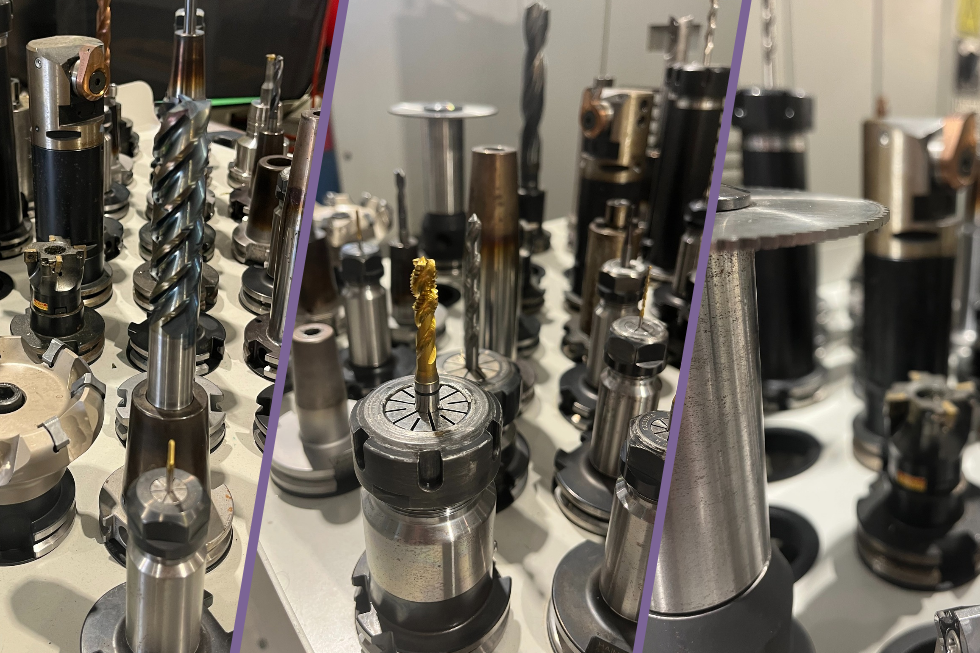

At the heart of CNC machining are the machine tools themselves – the cutters, drills, mills, and lathes that bring designs to life. Understanding how milling, turning, and drilling tools work is essential, not only for machinists but also for procurement teams and engineers looking to source reliable CNC machining services in the UK.

In this article, we’ll explore the key tools used in milling, turning, and drilling CNC operations, their applications, and how the right choice of tooling enables manufacturers such as Tarvin Precision to deliver outstanding results.

Why CNC Machining Tools Matter

Every CNC machine is only as good as the tools it uses. While computer numerical control ensures precision, the actual interaction with the material happens at the tool’s cutting edge. Choosing the correct tool:

- Improves accuracy and dimensional tolerance.

- Reduces waste by minimising errors.

- Enhances surface finish for parts that must meet strict cosmetic or functional standards.

- Optimises production speed, lowering costs and lead times.

For UK manufacturers competing in global supply chains, efficiency and quality are non-negotiable. That’s why at Tarvin Precision, we invest not only in high-quality CNC machines but also in the tooling strategies that unlock their full potential.

Milling CNC Machine Tools

Milling tools are designed to cut away material using rotary cutters, producing flat surfaces, contours, slots and complex 3D shapes. In CNC machining across the UK, milling is one of the most common processes, essential for everything from prototype development to low-volume production runs. The choice of milling tool depends on the geometry required, the hardness of the material, and the desired surface finish. With the rise of multi-axis machining, milling tools now play an even greater role in producing complex aerospace and medical components in fewer setups, increasing efficiency and accuracy while reducing waste.

1. Slab Mills

Slab mills are heavy-duty tools used to machine large, flat surfaces. They are often applied during the initial stage of machining to prepare a clean, level base for further operations. By removing significant amounts of material quickly, slab mills improve efficiency when dealing with sizeable workpieces.

2. End Mills

Arguably the most versatile milling tool, end mills can cut in multiple directions, making them suitable for pockets, slots, profiles, and even drilling. Their subtypes include:

- Flat end mills– for sharp edges and flat-bottomed cuts.

- Ball nose end mills– for 3D contours and smooth curved surfaces.

- Bull nose end mills– for strength in heavier cuts and fillets.

This versatility makes them indispensable in aerospace and medical engineering – two sectors where CNC machining UK plays a crucial role.

3. Fly Cutters

Fly cutters are cost-effective tools for creating broad, shallow cuts and achieving a smooth finish on large flat surfaces. They are especially valuable in applications where surface aesthetics and uniformity matter.

4. Hollow Mills

Unlike end mills, hollow mills cut externally around a workpiece, often used to create screw systems and cylindrical features. They also find use in finishing operations, producing clean and polished results.

5. Face Mills

Face mills are fitted with multiple replaceable cutting inserts and are designed for horizontal cutting. They are efficient for creating large, flat faces with excellent surface finish. Carbide inserts are commonly used, providing durability when cutting harder metals such as stainless steel or titanium.

6. T-Slot Cutters

T-slot cutters are specialised tools used to mill slots that resemble the “T” shape, which can hold fasteners or fixtures. They are essential in producing machine tables, jigs, and fixtures that require secure, sliding components. Their design allows them to cut undercut grooves that standard end mills cannot achieve.

7. Dovetail Cutters

Dovetail cutters are angled milling tools designed to produce dovetail-shaped grooves. These joints are widely used in mechanical assemblies for their strength and resistance to pull-out forces. In precision engineering, dovetail cutters are indispensable when producing sliding mechanisms or interlocking components that demand high accuracy.

Turning CNC Machine Tools

Turning operations are carried out on CNC lathes, where the workpiece rotates while the tool remains stationary. This method is ideal for cylindrical parts and is a cornerstone of industries requiring shafts, housings, and high-precision rotational components. Turning not only shapes materials quickly but also provides excellent repeatability, which is essential in sectors where consistency is critical. Advanced CNC lathes in the UK are often multi-axis, allowing complex geometries to be achieved in a single setup, reducing lead times and costs.

1. Chamfering Tools

Chamfering removes sharp edges, improving both safety and aesthetics. It also aids in assembly by easing part alignment and preventing damage to mating components.

2. Boring Tools

Boring enlarges pre-drilled holes to precise diameters and can be used for straight or tapered geometries. This is particularly critical in industries like defence and aerospace, where precision bore diameters affect mechanical performance.

3. Parting Tools

Parting tools cut off sections of material, separating a finished part from stock or removing unwanted sections. Their accuracy ensures clean separations, reducing the need for secondary finishing.

4. Knurling Tools

Knurling tools impress textured patterns onto cylindrical surfaces, providing grip for hand-operated parts such as knobs or fasteners. They can also be used decoratively in custom applications.

5. Threading Tools

Threading tools are designed to cut precise screw threads on the inside or outside of cylindrical components. These are vital for creating fasteners, fittings, and joints that must meet international standards for pitch, depth, and strength. In aerospace and defence projects, accurate threading is critical to ensure secure, vibration-resistant assemblies.

6. Grooving Tools

Grooving tools cut narrow channels into the workpiece surface, either externally or internally. These grooves may serve functional purposes, such as accommodating O-rings or retaining clips, or they may form part of a more complex geometry. High-precision grooving is often required in hydraulic systems and scientific instrumentation.

For companies seeking CNC machining in the UK, turning tools are essential in delivering round and symmetrical parts with the tight tolerances required in advanced engineering applications. From precision hydraulic shafts to aerospace-grade fasteners, the correct use of turning tools — whether chamfering, threading, or grooving – ensures durability, performance, and compliance with strict industry standards.

Drilling CNC Machine Tools (Drill Bits)

Drilling is the process of creating holes, an essential step in nearly every CNC project. Modern CNC drill bits are engineered for speed, accuracy, and material compatibility, ensuring that holes are produced to exact specifications. Choosing the correct drill bit is vital, as different materials and depths demand different geometries and cutting capabilities. In many cases, drilling also serves as the foundation for subsequent operations, such as boring, tapping, or reaming, making it a critical stage in CNC machining.

1. Twist Drills

These are the most widely used drill bits, ideal for general-purpose hole-making. They come in a wide range of diameters and can cut through metals, plastics, and composites. With proper coatings, such as titanium nitride, twist drills can extend tool life and deliver clean, consistent holes.

2. Ejector Drills

Ejector drills excel at deep-hole drilling, providing a mechanism for removing chips while maintaining accuracy. They are invaluable in industries where deep, precise bores are required, such as aerospace fuel systems or hydraulic equipment. Their ability to maintain straightness over long depths sets them apart from conventional drills.

3. Centre Drills

Centre drills are used to mark and start holes, preventing wandering when using larger drill bits. They act as guides for subsequent drilling operations, ensuring accuracy. They are particularly important when machining high-precision components where hole placement is critical to overall part performance.

4. Step Drills

Step drills are conical-shaped tools designed to create holes of multiple diameters with a single bit. They are especially useful when machining thin materials, as they reduce the risk of tearing and provide smooth transitions between diameters. In CNC machining, step drills help minimise tool changes, improving efficiency in operations that require varied hole sizes.

5. Countersink Drills

Countersink drills are used to create a conical recess around a hole, typically for accommodating the head of a countersunk screw or fastener. They improve both the functionality and appearance of CNC-machined parts by ensuring that fasteners sit flush with or below the surface. In high-spec industries like aerospace, this not only improves aerodynamics but also prevents stress concentrations.

CNC Machining UK: Quality, Precision, and Capability

The UK has a rich tradition of engineering excellence, and CNC machining has strengthened its role in advanced manufacturing. With global competition increasing, buyers are looking for suppliers who combine technical expertise with reliability and responsiveness.

That’s where Tarvin Precision stands out. Based in the UK and certified to AS9100 Rev D, we specialise in low-volume, high-variety CNC machining and bespoke precision engineering. Our experience spans over three decades, supporting industries such as:

- Aerospace & Defence – delivering safety-critical components with full traceability.

- Scientific Research & Instrumentation – machining unique, complex parts to tight tolerances.

- Specialist Engineering Projects – offering rapid response to niche or one-off requirements.

We don’t just run CNC machines – our experience team applies a deep knowledge of tooling, programming, and materials to achieve results that matter to our clients. Whether it’s milling with precision face mills, turning with specialised boring tools, or drilling intricate features with ejector drills, our capabilities are matched by a commitment to customer success.

The Future of CNC Machining Tools

Tooling technology is evolving rapidly. In the UK, many CNC machining companies are adopting:

- Carbide and ceramic inserts for extended tool life.

- Coated tools (e.g., TiN, TiAlN) for higher cutting speeds and better wear resistance.

- Multi-axis tooling strategies for reduced setups and faster cycle times.

- Digital tool monitoring to detect wear and optimise usage.

By staying at the forefront of technological advances, Tarvin Precision ensures that our customers benefit from the most efficient, reliable and cost-effective CNC machining solutions available in the UK.

The Right Tools for Precision

Understanding milling, turning, and drilling CNC machine tools is fundamental to achieving the high standards of precision, efficiency, and quality demanded in modern manufacturing. From slab mills, T-slot cutters and dovetail cutters in milling, to boring, threading and grooving tools in turning, and specialised drill bits such as ejector drills, step drills and countersink drills, each tool serves a unique purpose in shaping raw material into finished components.

For buyers seeking CNC machining in the UK, this knowledge underscores the value of working with a supplier that combines technical expertise with advanced tooling strategies. At Tarvin Precision, we draw on over three decades of experience and AS9100 Rev D certification to deliver low-volume, high-variety CNC machining solutions across aerospace, defence, scientific research and specialist engineering sectors. By leveraging the right tool for the right job, we ensure every part meets exacting standards – whether it’s a prototype, a one-off, or a critical production component.

Partner with us today and see how our CNC machining expertise in the UK can bring your designs to life with accuracy and reliability. Send us a quick message or request a quote.