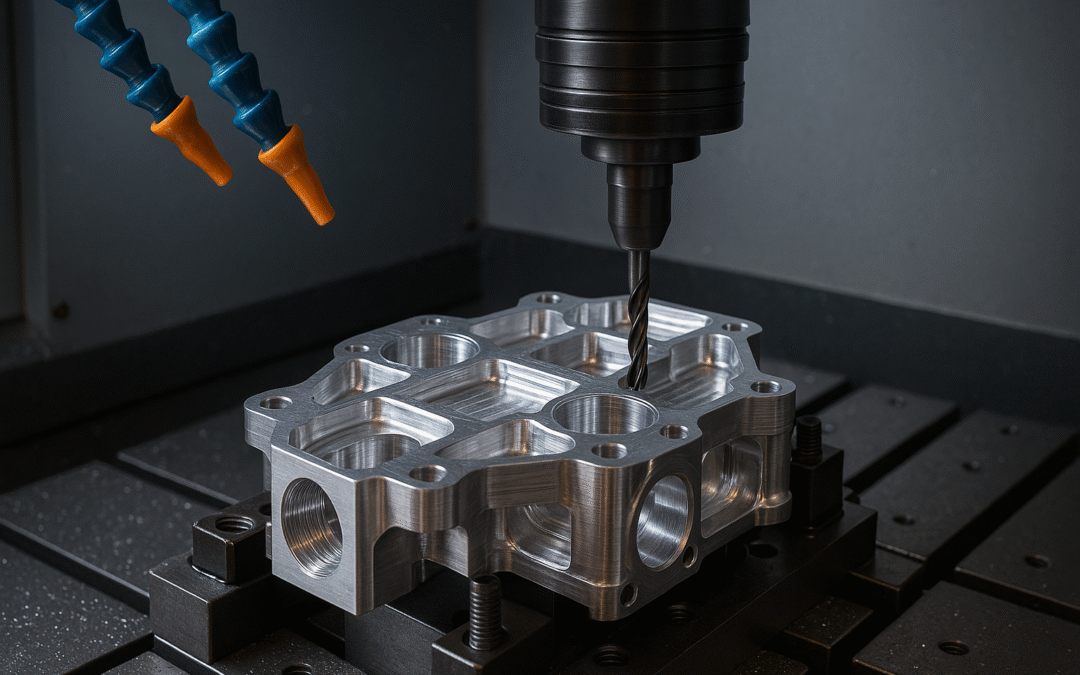

AS9100 machining buyers are not just looking for a CNC machine shop, they are looking for a controlled, auditable and repeatable process that can survive aerospace-level scrutiny. AS9100 certification is the quality backbone behind many of the most demanding programmes in aviation, defence and space. This a direct impact on how precision machining is planned, executed, inspected, and documented.

This article explains what AS9100 means in a machining context, how it goes beyond ISO 9001 and what you should expect from an AS9100-certified machining partner. Along the way, we’ll use Tarvin Precision as an example of how a UK subcontract machinist applies AS9100 in practice.

What is AS9100 and Why It Matters for Machining

AS9100 is an international aerospace quality management standard formally titled “Quality Management Systems – Requirements for Aviation, Space and Defense Organizations.” It builds on ISO 9001 and adds aerospace-specific requirements around safety, reliability and regulatory control.

Unlike general-purpose quality standards, AS9100 is written for organisations that design, manufacture and support aerospace products. That includes:

- Precision machining suppliers producing structural and non-structural components

- Manufacturers of engine components, actuation systems and landing gear parts

- Defence and space supply chain partners working on low-volume, high-complexity work

For CNC machine shops, AS9100 machining essentially means machining performed within an AS9100-compliant quality management system (QMS). The machines themselves are only one part of the equation; the QMS is what ensures:

- Systematic control of risk and variation

- Full traceability of material, processes and inspection data

- Robust control of design changes, configuration and documentation

- Structured, evidence-based continuous improvement

This is why many primes and Tier 1s will only place work with suppliers listed in OASIS (the Online Aerospace Supplier Information System) as certified to AS9100 or EN 9100.

AS9100 vs ISO 9001 in a Machining Environment

AS9100 incorporates ISO 9001 in full, then layers on aerospace-specific requirements. In a CNC machining context, some of the key differences include:

Stronger focus on risk-based thinking

ISO 9001:2015 first introduced risk-based thinking, but AS9100 pushes it much further. Risk is embedded in planning, operations, and change control. Shops must systematically identify, evaluate, and mitigate risks that could affect product conformity or safety, for example:

- Risk of machining distortion on thin-wall aerospace brackets

- Risk of tool wear leading to out-of-tolerance bores on a safety-critical part

- Risk of programming errors when introducing a new 5-axis machining strategy

AS9100D includes explicit clauses around operational risk management (e.g. clause 8.1.1) and requires actions to be proportionate to the impact on product conformity and safety.

Product safety and configuration management

AS9100 introduces specific controls for product safety, including prevention of counterfeit parts, management of foreign object debris (FOD) and handling of safety-critical features.

For a machining supplier this means:

- Tightly controlled programming and setup documentation

- Verification of all key features and interfaces

- Strict control of configuration and revision status on CAM data, models and drawings

Key characteristics and variation management

The standard emphasises key characteristics – features whose variation has a significant effect on product performance or safety and therefore require dedicated control and monitoring.

In machining, key characteristics might include:

- Bearing diameters on rotating components

- Hole positions affecting assembly alignment

- Surface finish on sealing faces

- Flatness or parallelism affecting structural load paths

AS9100 machining means identifying these features, assigning appropriate control methods (e.g. capability studies, SPC, 100% inspection) and documenting the approach in control plans.

Enhanced supplier and special process control

Most aerospace components involve special processes such as heat treatment, NDT, plating and coating. AS9100 precision engineering companies must be able to demonstrate robust selection, monitoring and control of these sub-tiers, often including Nadcap accreditation or prime approvals where required.

For a buyer, this is a critical part of risk reduction: choosing an AS9100 machining partner means you are plugging into a controlled and monitored wider supply chain, not just a set of machines.

How AS9100 Shapes the Machining Process: Step by Step

Although every company has its own methods, an AS9100 machining workflow typically follows a structured lifecycle from RFQ through to delivery. Below is a simplified view of what you should expect.

1. Enquiry and contract review

Under AS9100, contract review is much more than just pricing. The machining supplier must ensure that all requirements are understood, feasible and fully captured, including:

- Latest drawing and model revisions

- Customer and regulatory requirements (e.g. EASA, MOD, ITAR, EAR)

- Material specifications and approved sources

- Special process requirements and approved processors

- First Article Inspection (FAI) and reporting (AS9102)

- Packaging, labelling, and documentation requirements

At Tarvin Precision, for example, technical review of new aerospace machining work will typically combine engineering, quality and production input to ensure feasibility before quotation. This is especially the case for for low-volume, high-complexity parts.

2. Process planning and risk assessment

AS9100 machining requires the shop to plan the entire process in a controlled way. This often includes:

- Process flow – mapping each manufacturing step from goods-in to final inspection

- Operation sheets / route cards – capturing speeds, feeds, tooling, workholding and in-process checks

- Risk assessment / FMEA – identifying where the process could fail and what controls are necessary

- Control plans – defining inspection frequencies, sampling plans, and key characteristic controls

Risk-based thinking is central here. High-risk features may trigger:

- Additional in-cycle probing or in-process checks

- Dedicated fixtures to manage distortion

- Tighter tool life management

- 100% inspection or enhanced sampling

A mature AS9100 machine shop will typically maintain a library of proven process strategies for aerospace alloys like titanium, Inconel and high-strength aluminium, using them as a baseline and tailoring them per part.

3. Material control and traceability

AS9100 expects full traceability from raw material to finished component. That means:

- Incoming material checked against purchase order and specification

- Mill certificates linked to batch identifiers

- Clear marking or labelling throughout the process

- Positive identification of any splits, part transfers or rework routes

During machining, batch/serial information must remain intact so that any downstream issue can be traced back to its origin – including which bar or billet, which machine, which operator, and which inspection route.

4. CNC programming and validation

In an AS9100 machining environment, CNC programming is a controlled process:

- CAD/CAM files are revision-controlled and linked to the customer drawing/model

- Post-processors are validated to ensure output matches machine requirements

- Simulation and verification are used to reduce collision risk and validate toolpaths

- First prove-out runs are subject to enhanced inspection and sign-off

Any change to a toolpath that affects key characteristics, tooling, or machining strategy must be formally reviewed and documented via change control, not quietly adjusted on the shop floor.

5. Set-up, in-process control and verification

Machining of aerospace components typically involves:

- Qualified and documented set-up instructions, often with photos or 3D views

- Pre-set tooling with measured offsets and controlled life

- In-process measurement using CMM, probing, gauges or manual methods

- Clear reaction plans if results drift towards control limits

For example, an AS9100 machining supplier might use:

- In-machine probing to verify datum locations before each batch

- SPC charts on key diameters to track process stability

- Tool wear offsets automatically adjusted based on measured trends

This approach maintains process capability and avoids surprises at final inspection.

6. Final inspection, FAI, and documentation

Before parts are released, an AS9100-compliant QMS requires evidence that all requirements are met. This typically includes:

- Dimensional inspection reports (CMM or manual)

- Verification of surface finish and geometric tolerances where specified

- Review of special process certificates (heat treatment, coating, NDT etc.)

- Confirmation of any customer-specific quality clauses

- First Article Inspection (FAI) reports to AS9102 for new or changed parts

AS9100 machining is as much about the evidence as the physical part. When an auditor or prime assesses the supplier, they expect to see a clear, traceable story from requirement through to measurement data and release.

Risk Management in AS9100 Machining

Risk management is not an optional extra; it is a core requirement in the latest revisions of AS9100 and it runs through every stage of how an aerospace component is machined. Rather than relying on experience alone, risks are identified, evaluated and controlled in a structured way so that the likelihood and impact of failure are reduced before any parts reach the customer.

Technical risk

Technical risk covers the fundamental engineering challenges of making the part: tolerance stack-ups, the behaviour of thin walls, residual stresses and distortion once clamping forces are removed. In an AS9100 machining environment these risks are analysed up front, often using simulation, trials and detailed process planning. Fixturing, cutting strategies and inspection plans are designed specifically to keep critical features stable and repeatable, and lessons learned from previous, similar parts are deliberately fed into new jobs so that the same problems are not rediscovered on every project.

Process risk

Process risk is about whether the method of manufacture can reliably deliver the required quality and quantity. Factors such as machine uptime, tool wear and breakage, coolant performance, operator competence and potential bottlenecks are all considered. An AS9100 subcontract CNC machining partner will address these by standardising proven set-ups, controlling tool life, defining contingency routes where practical, and ensuring that operators are trained and authorised for the work they do. The aim is to remove variability from the process so that every batch is produced under known, controlled conditions.

Supply chain risk

Supply chain risk recognises that even the best internal process can be undermined by weak links in external sourcing. Aerospace machining relies on certified material mills and special process providers for heat treatment, coatings and NDT. Under AS9100, these suppliers are selected, approved and regularly reviewed against defined criteria for quality, lead time and reliability. Alternate sources are identified where possible, and any issues are escalated and captured through the quality system. This reduces the chance of late deliveries, uncertified material or unapproved special processes affecting the finished parts.

Compliance risk

Compliance risk focuses on the possibility of misinterpreting or missing customer, legislative or regulatory requirements. Drawings, models, specifications and contract clauses can be complex, and errors here can be costly. An AS9100 machining supplier manages this by carrying out rigorous contract review, clarifying ambiguities before work starts, and tightly controlling configuration and revision status throughout the job. This ensures that the parts produced genuinely meet the intent of the design authority and the expectations of regulators and end users.

An AS9100 machining supplier must:

Identify risks during planning (for example using FMEA or structured risk matrices).

Implement appropriate controls such as extra inspections, trial runs or alternate routings.

Document the decisions taken and the outcomes achieved.

Review the effectiveness of those actions and feed lessons back into future jobs.

This risk-driven approach greatly reduces the chance of late-stage non-conformances, rework or field issues – which is exactly what primes and Tier 1s want to see from their machining partners.

Materials and Special Processes in AS9100 Machining

Aerospace and defence parts often use demanding materials, including:

- Titanium alloys (e.g. Ti-6Al-4V)

- High-strength aluminium alloys (e.g. 7075, 7050)

- Nickel-based superalloys (Inconel, Hastelloy)

- Stainless steels and maraging steels

AS9100 machining suppliers must demonstrate control over:

- Material selection and purchasing from approved sources

- Machining parameters tuned for each alloy to manage heat, work hardening and tool life

- Stress-relief operations and heat treatment where required

- Surface treatments, coatings, and NDT to customer or prime specifications

Here, a company like Tarvin Precision leverages its experience in high-variety, low-volume aerospace work to select appropriate tooling, strategies and fixturing out of the gate, reducing prove-out time while staying within AS9100’s documented, validated process framework.

Measurement, Inspection and Metrology Under AS9100

AS9100 expects calibrated, controlled measurement systems. In AS9100 machining, you should expect:

- CMMs, vision systems, surface testers and gauges with current calibration certificates

- MSA (Measurement System Analysis) where appropriate for key characteristics

- Clear definition of which features are checked 100%, which by sampling and why

- Control of software versions for metrology equipment

Measurement data is not just stored and forgotten. In a mature AS9100 machining environment it is analysed for:

- Trends in process capability (Cp, Cpk)

- Drift in machine geometry or fixturing

- Opportunities to optimise cycle times without sacrificing capability

Benefits of Choosing an AS9100 Machining Partner

When you specify AS9100 machining, you are buying far more than a set of components. You are selecting a supplier whose entire operation is built around aerospace-level control, traceability and accountability. That has a direct impact on risk, quality, and how easy it is to work with them throughout the life of a programme.

Reduced supply chain risk

An AS9100-certified machining partner has already been tested against a recognised aerospace standard, so much of the risk has been removed before you even place an order. Their quality system, documentation and methods have been independently assessed, and they will have proven processes for handling non-conformances, configuration control, and changes to specification. This means fewer surprises, fewer escalations, and a more predictable flow of conforming parts into your business.

Improved product safety and reliability

A core focus of AS9100 is product safety. An AS9100 machining partner treats safety-critical features, key characteristics and potential failure modes with additional control and visibility. From programming and fixturing through to inspection and release, safety-related aspects are highlighted, given defined control plans, and monitored for variation. This ensures that the components you receive are not only within tolerance, but produced by a process that actively manages the risk of failure over the life of the part.

Faster root cause analysis and problem resolution

When something does go wrong, the strength of an AS9100 machining partner really shows. They are required to use structured Corrective and Preventive Action (CAPA) processes, backed up by detailed, retained production and inspection data. This makes it much easier to identify the real root cause of an issue, whether it sits with tooling, programming, material, or a special process, and to put robust corrective actions in place. For the customer, that translates into faster resolution, fewer repeat issues, and clear evidence that lessons have been learned.

Easier customer and regulatory approvals

Because AS9100 is widely recognised across the aerospace, defence and space sectors, an AS9100 machining supplier is already working in a language that primes, Tier 1s and regulators understand. Their presence in OASIS and their audit history provide confidence that they can support customer approvals, first article inspections and ongoing surveillance. This alignment with industry expectations simplifies supplier onboarding and makes it easier to demonstrate due diligence to customers and regulatory bodies.

Scalable, repeatable performance

Finally, an AS9100-based quality management system is designed to be scalable. As programmes grow, volumes change or new references are introduced, the same disciplined approach to planning, risk assessment, documentation and verification applies. Processes are defined, repeatable and auditable, rather than being dependent on individual operators. That gives you confidence that the machining partner can support new programmes and higher complexity without losing control – and that performance achieved on day one can be maintained over years of production.

How Tarvin Precision Applies AS9100 Machining in Practice

As a UK-based subcontract machining specialist, Tarvin Precision uses AS9100 certification as the framework for delivering low-volume, high-variety aerospace and defence components with the same rigour you would expect from a prime.

AS9100-driven process design

Each new aerospace part is routed through structured contract review, risk assessment and process planning before any metal is cut. This ensures feasibility, clarity on special processes, and alignment with customer quality clauses from day one.

Audit-ready traceability and documentation

Material batches, process steps, inspection results and special process certificates are all tied back to the job and, where required, to individual serial numbers. This supports audits by primes and third-party certification bodies.

Focus on agility without losing control

Aerospace supply chains increasingly need suppliers who can respond quickly to schedule changes and urgent requirements. Tarvin Precision leverages its size and flexible machining capability while still operating within the discipline of AS9100, proving that agility and compliance can coexist.

Integration with defence and security expectations

With credentials such as Cyber Essentials Plus in place for defence work, Tarvin’s AS9100 machining capability is combined with appropriate information security controls, supporting secure handling of sensitive drawings and models.

For buyers seeking AS9100 machining in the UK, this combination of standard-compliant quality and responsive subcontract capacity can significantly de-risk programmes while improving time to market.

What to Look for When Selecting an AS9100 Machining Supplier

If you are sourcing AS9100 machining for a new or existing programme, a structured evaluation pays off. Points to consider:

Certification scope and status

- Are they certified to AS9100 or EN 9100?

- Does the certificate scope explicitly include CNC machining, turning, milling, or the processes you require?

- Is the certificate current, and can you verify it via OASIS?

Experience with similar components and materials

- Do they routinely machine parts of similar complexity, tolerances, and materials?

- Can they share anonymised examples of inspection results or process controls?

Approach to risk and key characteristics

- How do they identify and control key characteristics?

- What tools do they use for risk assessment (FMEA, risk registers, etc.)?

Inspection and metrology capability

- Do they have appropriate CMM capacity and expert programmers?

- Can they support AS9102 First Article Inspection reporting?

Special process and supplier network

- Are key subcontractors (heat treat, coatings, NDT) approved to suitable standards (e.g. Nadcap, prime approvals)?

- How do they control and monitor those suppliers?

Cultural fit and communication

- Are engineering and quality teams accessible and collaborative?

- Do they provide clear, timely communication around deviations, risks, and opportunities for improvement?

When a shop like Tarvin Precision ticks these boxes and backs them up with AS9100 certification, you are not just buying machining capacity. You are adding a controlled, auditable, and responsive aerospace-grade partner to your supply chain.

AS9100 Machining: The Right Partner for Precision

In an industry where failure is not an option, AS9100 machining is less about achieving a badge and more about embedding a disciplined way of working into every cut, every measurement, and every decision. For aerospace, defence, and space buyers, working with an AS9100-certified machining partner such as Tarvin Precision is one of the most effective ways to strengthen quality, reduce risk and build long-term supply chain resilience.