What is AS9100? AS9100 is the quality management system (QMS) standard used across the aviation, space and defence supply chain. It builds on ISO 9001 and adds aerospace-specific requirements that help organisations control risk, manage configuration (revision control), improve traceability, and prevent issues like counterfeit parts entering the supply chain.

At Tarvin Precision, we’re often asked this question by engineering and procurement teams who need confidence that a supplier can reliably deliver tight-tolerance CNC machining and build-to-print assembly with the right controls behind it. In this article, we’ll explain AS9100 in plain English, then translate it into what it means on the shop floor – quoting, planning, machining, inspection, documentation, and assembly – so you can assess suppliers with clarity.

What AS9100 Actually Is

AS9100 is a globally adopted aerospace QMS standard created under the International Aerospace Quality Group (IAQG) umbrella, using ISO 9001 as the baseline and adding requirements specific to aviation, space and defence.

In practice, AS9100 is less about “extra paperwork” and more about repeatability: making sure the right part is made, from the right material, to the right revision, verified the right way, and supported by the right evidence, every time.

Why Aerospace and Defence Put So Much Emphasis on AS9100

Aerospace and defence supply chains are high consequence. A minor deviation that might be tolerable in a consumer product can become a major nonconformance when parts are destined for aircraft, satellites, flight test rigs, optics, or mission-critical defence systems. AS9100 exists to reduce that risk by forcing organisations to treat quality as a controlled system rather than a best-efforts outcome.

Here are a few reasons AS9100 becomes a “must-have” (or a strong preference) in many programmes:

- Safety and reliability expectations are higher, with stricter controls and accountability.

- Traceability is often contractually required (material heat/lot, batch control, serialisation).

- Configuration changes are common and must be controlled so the wrong revision isn’t built.

- Supply-chain risk is real (external processing, purchased parts, subcontractors).

- Customer audits are frequent, and evidence matters.

AS9100 vs ISO 9001: What’s the Difference?

It’s accurate to say AS9100 is “ISO 9001 plus aerospace requirements,” but that undersells the impact. ISO 9001 sets broad requirements for managing quality in any industry. AS9100 keeps that structure but strengthens areas that repeatedly cause issues in aerospace: operational risk, configuration control, traceability, supplier control, product safety, and counterfeit parts prevention.

What aerospace buyers typically feel as the difference is this: AS9100 creates a tighter, more auditable chain from requirement → plan → process → verification → release.

Key additions and emphasis areas you’ll see in AS9100 environments include:

- Operational risk management integrated into planning and production expectations

- Configuration management (knowing and controlling the “as-built” state vs the required state)

- Product safety process expectations (especially strengthened in Rev D)

- Counterfeit parts prevention controls (especially relevant to purchased parts and assemblies)

- More robust supplier control (outsourced processes like heat treat, plating, NDT, etc.)

Which Version Matters Today: AS9100 Rev D (AS9100D)

Most organisations you speak to today are working to AS9100 Rev D (AS9100D), which aligns with ISO 9001:2015’s structure and strengthens aerospace themes such as product safety and counterfeit parts prevention.

For customers, the practical takeaway is that AS9100D pushes suppliers to be more deliberate about preventing problems rather than just reacting to them. That shows up in how jobs are planned, how changes are controlled, and how evidence is collected.

What “AS9100 Certified” Means (And What It Doesn’t)

AS9100 certification typically means a third-party certification body has audited an organisation’s quality management system against AS9100 requirements and confirmed it’s being implemented and maintained. It’s a strong signal of maturity, but it’s not a magic shield – customers still need to confirm scope, capability, and how the supplier manages high-risk characteristics. (In other words: certification helps you shortlist; it doesn’t replace technical due diligence.)

When you’re reviewing a supplier’s AS9100 status, check for these basics:

- The scope of certification (does it include machining, assembly, inspection, etc.?)

- The sites covered (is the work actually done at the certified location?)

- Any exclusions or limitations (rare, but worth understanding)

- Whether key processes are in-house or outsourced, and how outsourced providers are controlled

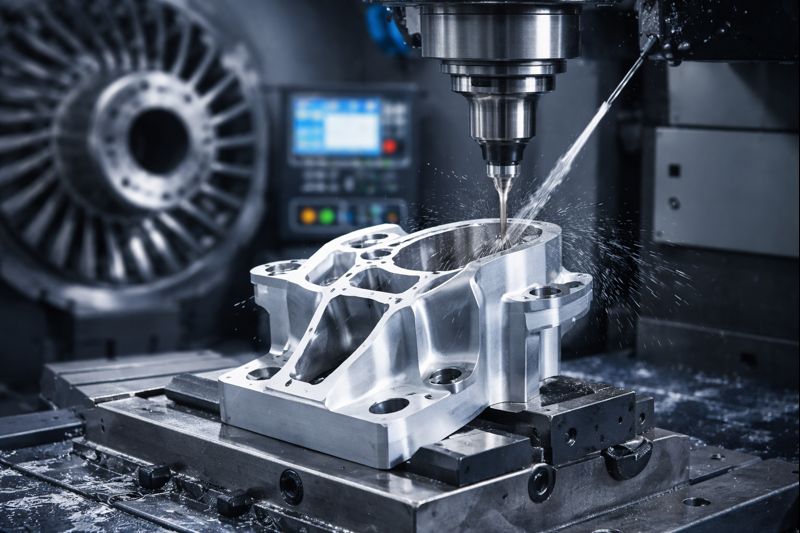

What AS9100 Looks Like in CNC Machining (From Quote to Dispatch)

AS9100 as the aerospace standard becomes real in the everyday habits of a machining business: how requirements are reviewed, how planning is done, how changes are controlled, and how conformity is proven. If you’re buying aerospace or defence CNC machining, the most important question isn’t “Do you have a certificate?” – it’s “Do your controls reliably prevent the failure modes we care about?”

Below are the main areas where AS9100 directly shapes CNC machining performance.

Contract Review and Requirement Capture

Before a job hits the shop floor, AS9100 machining expectations drive a structured review of requirements so nothing critical is missed. This is where you avoid classic failures like machining to the wrong revision, missing a spec call-out, or overlooking packaging and cleanliness requirements.

Common checks during contract review include:

- Drawing/model and revision status confirmation

- Applicable specifications (materials, finishes, special process notes)

- Identification of key characteristics / critical features

- Inspection requirements (e.g., FAI expectation, customer-specific formats)

- Documentation expectations (CoC wording, traceability level, serialisation)

- Handling, preservation, and packaging requirements (especially for surface-critical parts)

Planning, Routers, and Controlled Work Instructions

AS9100 environments typically formalise how a job is planned and released to production. That doesn’t mean bureaucracy for its own sake – it means you can consistently answer: “What did we do, who did it, with what tools, to what revision, and how was it verified?”

In a machining context, controlled planning often includes:

- Operation sequencing (including inspection gates)

- CNC programme control and verification approach

- Tooling approach (especially for repeat work and key features)

- Defined measurement method for tight tolerances

- Defined reaction plan if results trend out of control

Calibration and Measurement Control (Critical for Tight Tolerances)

Calibration and Measurement Control (Critical for Tight Tolerances)

Precision machining is only as trustworthy as the measurement system behind it. AS9100 requires controlled measuring equipment and calibration systems so inspection results are defensible during audits, investigations, or concession discussions.

Practical examples of measurement control include:

- Equipment registers and calibration status checks

- Controlled use of gauges (who can use what, and when)

- Environmental considerations where relevant (temperature stability for precision work)

- Traceability of results to the equipment used

In-process Inspection and Statistical Thinking (Where It Matters)

AS9100 doesn’t force a single inspection method, but it does push organisations to plan verification and treat risk appropriately. In machining, this often means adding in-process checks on features that are expensive to scrap late, or that are known to move with tool wear, heat, or material variation.

Typical strategies include:

- Early “proof” checks before committing to full cycle runs

- Defined check frequency for drifting dimensions

- Separate verification for critical features (e.g., bores, datums, interfaces)

- Clear escalation rules if results approach tolerance edges

Traceability: Proving the Chain from Material to Finished Part

Traceability is one of the biggest day-to-day differences customers notice when moving from general engineering to aerospace work. AS9100’s focus on control and evidence supports traceability expectations across aviation, space and defence contexts. i

Depending on contract requirements, traceability can include:

- Material certification and heat/lot linkage

- Batch/serial identification and controlled labelling

- Record linkage through outsourced processes (e.g., plating certs tied to the job batch)

- Preservation of records for the required retention period

Control of Outsourced Processes and Special Processes

Many machined aerospace parts rely on subcontracted processes (heat treat, anodising, plating, passivation, NDT). AS9100 strengthens expectations around selecting, monitoring, and controlling external providers so the final part still meets requirements.

What good control tends to look like:

- Approved supplier lists and performance monitoring

- Purchase orders that clearly state flowed-down requirements

- Verification of certificates and traceability on return

- Clear segregation of conforming vs nonconforming returns

Nonconformance Control and Corrective Action (How Problems Are Handled)

In aerospace, customers care just as much about how you respond as the fact that an issue occurred. AS9100 environments are expected to contain issues, prevent escape, and implement corrective action proportionate to risk.

A robust approach typically includes:

- Immediate segregation and clear identification of nonconforming product

- Documented disposition (rework, scrap, concession request where permitted)

- Root cause analysis and corrective action when required

- Evidence that corrective actions are effective (not just “we reminded the operator”)

What AS9100 Means for Aerospace and Defence Assembly

AS9100 matters just as much in assembly as it does in machining—sometimes more—because assembly introduces purchased parts, kitting, configuration control, and process steps that can be difficult to “inspect quality into” at the end. The standard pushes organisations to build control into the process so the final assembly is predictable and traceable.

Here are the assembly areas that usually tighten up under AS9100.

Configuration Control, BOMs, and “As-built” Records

In build-to-print assembly, the biggest silent risk is building the wrong configuration: the wrong revision, an unapproved substitute, or a mixed batch of parts with unclear traceability. AS9100’s configuration management emphasis is designed to prevent that.

In practice, good configuration control includes:

- Released BOMs and drawings with controlled revision status

- Kitting controls to prevent part mixing

- Serialisation and “as-built” documentation where required

- Controlled change process for any deviations or substitutions

Counterfeit Parts Prevention (Especially Relevant to Purchased Parts)

Counterfeit and suspect CNC machining parts are a known supply chain risk, and AS9100 requires organisations to implement controls to prevent counterfeit parts from entering the product. This is particularly relevant when assemblies include bought-in items such as fasteners, bearings, electronics, connectors, or specialist hardware.

Controls often include:

- Approved sourcing routes and supplier verification

- Receiving inspection proportionate to risk

- Traceability records linking purchased items to builds

- Quarantine and escalation process for suspect items

Process Discipline: Torque, Bonding, Cleanliness, ESD, and Test Evidence

Assembly quality is often determined by process discipline: doing the right step the right way, with the right tooling, and recording evidence that it happened. AS9100 encourages that mindset by requiring planned controls and objective evidence where needed.

Depending on the product, assembly controls may include:

- Torque tool control and recorded torque steps

- Adhesive/bonding controls (mix ratios, cure times, shelf-life, batch traceability)

- Cleanliness controls and preservation methods

- ESD handling (for electronic and electro-optical assemblies)

- Functional checks, leak tests, or other verification with retained results

AS9100 vs AS9110 vs AS9120 (So You Choose the Right Expectation)

It’s common to see related “AS91xx” standards and assume they’re interchangeable. They’re not; they’re aimed at different parts of the aerospace ecosystem. AS9100 is the manufacturing-focused standard, while AS9110 is typically associated with maintenance/repair/overhaul and AS9120 with distributors.

A simple way to interpret them:

- AS9100: manufacturing (CNC machining, production, build-to-print assembly)

- AS9110: MRO / maintenance organisations

- AS9120: stockists and distributors

If you need a supplier to make parts and assemblies, AS9100 is typically the relevant baseline.

What to Ask An AS9100 CNC Machining Supplier (Buyer’s Checklist)

When you’re researching aerospace engineering companies and qualifying a supplier – especially for first-time aerospace/defence work – having a short, consistent set of questions helps you compare apples with apples. AS9100 supports many of these expectations, but the supplier’s answers will tell you how mature their system really is.

Here’s a practical checklist you can use during onboarding, audits, or even early RFQ conversations:

- Revision control: How do you ensure the shop only works to the latest drawing/model revision?

- Traceability: What level of material and process traceability can you provide as standard?

- Inspection: What’s your approach to verifying tight tolerances (and what equipment do you use)?

- FAI: Can you support First Article Inspection packages when required (and what format)?

- Special processes: Which processes are outsourced, and how are subcontractors controlled?

- Nonconformance: How do you contain, disposition, and prevent recurrence of issues?

- Documentation: What is included in the standard release pack (CoC, material certs, inspection reports)?

- Assembly controls (if applicable): How do you manage kitting, torque control, bonding, ESD, and test records?

Common misconceptions about AS9100

AS9100 is widely referenced, so it attracts myths – some optimistic, some cynical. Understanding what it does and doesn’t guarantee helps you make better supplier decisions and reduces surprises during programme delivery.

A few misconceptions we hear regularly:

- “AS9100 guarantees perfect parts.” No system can guarantee zero defects, but it should reduce risk and improve response when issues occur.

- “If you have AS9100, you must be expensive.” AS9100 should reduce cost of poor quality; good systems often lower total cost over time.

- “It’s just paperwork.” The strongest AS9100 shops use documentation to support control, not to replace competence.

- “Any AS9100 supplier can make any aerospace part.” Certification isn’t the same as capability—materials, tolerances, processes, and inspection capacity still matter.

How We Approach AS9100 at Tarvin Precision

As a UK CNC machining and assembly supplier, our goal is to make AS9100 useful to customers – not performative. That means building a system that supports repeatability in the things aerospace and defence customers care about: capturing requirements accurately, controlling revision status, planning the job properly, verifying conformity with calibrated measurement, and maintaining traceability through to dispatch.

In practical terms, customers typically work with us when they need a supplier that can support:

- Tight-tolerance CNC machined components with controlled inspection and documentation

- Build-to-print sub-assemblies with configuration control and objective evidence

- Traceability packs aligned to flowed-down aerospace/defence requirements

- A “Made in Britain” approach where manufacturing, quality control, and communication are handled in the UK (supporting shorter feedback loops and clearer accountability)

FAQ: What is AS9100?

Many people searching “What is AS9100?” want a quick, practical answer they can use when qualifying a CNC machining or assembly supplier for aerospace and defence work. The FAQs below cover the most common questions we hear from engineering, quality, and procurement teams – focused on what AS9100 means in real-world terms, what evidence you should expect, and how it supports traceability, inspection, and controlled production.

Is AS9100 the same as ISO 9001?

AS9100 includes ISO 9001 requirements as a base and adds aerospace-specific requirements such as configuration management, product safety, risk emphasis, and counterfeit parts prevention.

What is AS9100D?

AS9100D (Rev D) is the commonly used modern revision of AS9100, aligned with ISO 9001:2015’s structure and strengthened for aerospace needs like product safety and counterfeit parts prevention.

Does AS9100 apply to assembly as well as machining?

Yes. AS9100 is a QMS standard for aviation, space and defence organisations and applies across production activities, including machining, inspection, purchasing/supplier control, and build-to-print assembly.

Why does counterfeit parts prevention come up in AS9100?

Because aerospace and defence supply chains can be exposed to counterfeit or suspect components; AS9100 requires organisations to implement controls to prevent such parts entering the product.

What is AS9100? Key Takeaways for Aerospace & Defence Buyers

So, what is AS9100? It’s the aerospace quality management standard that builds on ISO 9001 and adds the extra controls aerospace and defence supply chains rely on, especially around risk, configuration (revision) control, traceability, supplier management, product safety, and counterfeit parts prevention. For CNC machining and build-to-print assembly, AS9100 is essentially a framework that helps ensure the right component is made and verified the right way, backed by objective evidence that stands up to audits and programme scrutiny.

Key points to remember from this guide:

- What is AS9100? A globally used aerospace QMS standard (ISO 9001-based) designed for aviation, space and defence expectations.

- It drives repeatability, reducing variation from quote → plan → manufacture → inspection → release.

- In CNC machining, it strengthens contract review, revision control, calibration, in-process verification, nonconformance handling, and traceability.

- In assembly, it reinforces configuration control, kitting discipline, bought-in parts verification, process controls (e.g., torque/bonding/ESD/cleanliness where applicable), and build records.

- It improves confidence in the supply chain by requiring tighter supplier and outsourced process control (e.g., heat treat, finishing, NDT).

- AS9100 certification is a strong indicator of maturity, but capability still matters – always confirm scope, equipment, and experience relevant to your parts and tolerances.

If your procurement or engineering team is assessing suppliers, asking “What is AS9100?” is a great start, but the real value comes from confirming how those controls show up in day-to-day machining and assembly on the jobs you care about.

Calibration and Measurement Control (Critical for Tight Tolerances)

Calibration and Measurement Control (Critical for Tight Tolerances)