If you’re looking for CNC machining parts, you probably need components that fit first time, arrive when promised and match your drawing without back-and-forth. This guide gives you the essentials – clearly and quickly – so you can brief suppliers with confidence, avoid delays and get dependable results on every batch.

Based on day-to-day shop-floor experience at Tarvin Precision (ISO 9001:2015, UK), you’ll learn how milling, turning and 5-axis/mill-turn differ; which materials and finishes suit real-world environments; what actually drives cost and lead time; how to structure an RFQ that gets fast, accurate quotes; and what “good” looks like in a supplier. The checklists and tips are vendor-neutral – use them whether you’re working with us or any other UK machining partner.

What Counts as CNC Machining Parts?

Before comparing quotes, it helps to be clear on terminology. CNC machining parts are build-to-print components made to your drawings and models on computer-controlled mills, lathes and multi-axis machines. They’re bespoke to your application – dimensions, fits, materials and finishes are defined by you – and they can range from one-off prototypes to recurring production runs with call-offs. This is different from CNC spare parts, which are items used to repair or maintain the machine tool itself (e.g., toolholders, spindles, ball screws).

In scope are both milled and turned features (and hybrids via mill-turn/5-axis), plus any post-processing such as heat treatment, anodising/plating, passivation, bead-blast, laser marking and assembly of inserts. A typical subcontract CNC machining order includes a 3D STEP/Parasolid model and a dimensioned PDF drawing with revision, units and tolerancing standard, along with notes for surface finish, threads, and inspection. Depending on your sector, you might also require material certificates (EN10204 3.1), first-article inspection (FAIR/ISIR), PPAP levels, serialisation and full traceability. In short: if the part’s geometry, performance or documentation matters to your product, it likely counts as a CNC-machined part.

Common examples include:

- Housings and covers with pockets, bosses, threaded holes and sealing faces (often aluminium 6082/6061 or plastics like POM/PEEK).

- Brackets, mounts and frames where positional accuracy and stiffness are important, including lightweight 5-axis aerospace brackets.

- Fluid and pneumatic components such as manifolds, valve bodies, adaptors and end caps with controlled bores and ports.

- Rotational parts – shafts, sleeves, bushings, spacers and threaded couplings, requiring tight concentricity from turning.

- Precision inserts and fixtures used in assemblies, tooling and test rigs, sometimes hardened or ground after machining.

- Instrumentation and electronics parts like heat sinks, sensor housings, camera mounts and optical mounts with consistent cosmetic finish.

- Lab/scientific components including plastic manifolds, sample holders and motion plates with engraving or marking for identification.

Whether simple or complex, the unifying theme is the same: geometry and finish are controlled by your drawing, and the part is manufactured accordingly on CNC equipment to meet those requirements.

Where CNC Machining Parts Are Used

Understanding typical applications early helps you brief suppliers faster and avoid over- or under-specifying your parts. The quick sector overview below shows common component types and what usually matters most (finish, accuracy, documentation). Use it as a checkpoint to align requirements before you move on to process selection, materials and finishing.

Aerospace

Lightweight brackets, housings, actuator components and tooling. Priorities: full traceability, first-article inspection, CMM reports and controlled cosmetic standards.

Medical & Scientific

Manifolds, surgical fixtures, instrument frames and cleanly finished plastics or stainless. Priorities: material certification, careful deburr/finish, serialisation and clear labelling.

Automotive & Motorsport

Hubs, mounts, timing covers and sensor housings. Priorities: consistent cosmetics on visible faces, repeatability across batches, and PPAP/FAI where required.

Energy, Marine & Offshore

Valve bodies, pump plates and impellers (often stainless or nickel alloys). Priorities: corrosion-resistant finishes, robust inspection of sealing/pressure faces, and durable markings.

Robotics & Electronics

Heat sinks, camera mounts and end-effectors. Priorities: tight positional accuracy, rigidity, thermal considerations and uniform cosmetic finish.

OEM Build-to-Print

Recurring batches across mixed part families. Priorities: stable pricing with call-offs, documented process control, and clear change/Revision management.

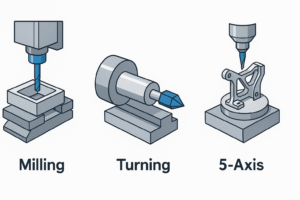

The Three Core Processes (And When to Use Each)

Choosing the right process improves accuracy, cost and lead time. Most work using CNC machining tools falls into milling, turning, or a hybrid approach. The quick overviews below show where each shines and how to design accordingly.

CNC Milling (3–5 Axis)

Best for prismatic shapes – plates, blocks, housings and pocketed parts. It’s a strong option when you need cnc machining milling parts with clean surfaces and tight positional accuracy.

Design tips: Use inside radii like R3–R6 for faster cutters; avoid deep, narrow pockets; group critical features on one face to reduce setups.

CNC Turning (With or Without Live Tools)

Ideal for rotational parts – shafts, sleeves, rings, threaded couplings and valve bodies. If your brief includes cnc machining turning parts with tight concentricity, this is the natural route.

Design tips: Make your reference faces/features unambiguous (e.g., control everything from the bore); avoid features that force re-chucking; use live tooling to add flats/slots in one hit.

Mill-Turn and 5-Axis Machining

For multi-face geometry, undercuts and organic contours – think manifolds, impellers, lightweight brackets and medical forms. This approach suits complex cnc machining precision parts that benefit from fewer setups and tighter geometric control.

When it helps: complex manifolds, aerospace brackets, medical fixtures and components with features on many faces.

Common UK Materials

Material choice drives machinability, performance and price. Start with function, then balance cost and availability. The notes below cover popular UK options used for CNC machining parts.

- Aluminium (6082-T6, 6061, 7075): Light, strong, very machinable – great for housings, frames, heatsinks and lightweight aerospace brackets. 6082-T6 is widely stocked.

- Stainless steel (303, 304, 316, 17-4PH): Corrosion resistance for medical, marine, food and scientific applications. 303 machines fastest; 316 excels in corrosion; 17-4PH can be precipitation-hardened. A popular choice for CNC machining services in the UK.

- Carbon/alloy steels (EN8/080M40, EN24T/817M40): Strong and cost-effective for shafts, gears and industrial parts; may need heat-treat.

- Titanium (Grade 2, Grade 5): High strength-to-weight and biocompatibility for medical and aerospace; slower cycles and premium tooling.

- Nickel alloys (Inconel, Monel): Heat/corrosion resistance for energy and offshore; require careful process control.

- Brass & copper: Outstanding machinability and conductivity for electronics and instrumentation.

- Engineering plastics (POM/Delrin, PEEK, PTFE, Nylon): Light, stable and often quick to machine – ideal for scientific and lab-automation components.

Spec tip: State the exact alloy and standard (e.g., Aluminium 6082-T6 to EN 573/755). Clear specs avoid delays and re-quotes.

Tolerances and Inspection

Tolerances determine both function and cost. Setting realistic limits, and agreeing how they’ll be checked, prevents surprises later.

- What’s realistic? For production, ±0.05 mm is a sensible default. Tighter (±0.01 mm or below) is achievable with the right process plan.

- Use GD&T where it helps: true position for hole patterns, flatness for sealing faces, concentricity on turned fits, profile for complex curves.

- Surface finish: Specify Ra where function requires it (e.g., Ra 1.6 µm on seals) and avoid over-specifying cosmetic areas.

- How parts are checked: In-process probing stabilises results; CMM/vision metrology verifies complex geometry.

- Documentation: Material certs (EN10204 3.1) as standard; FAIR/ISIR for first-offs; PPAP for automotive; serialisation and full traceability for regulated sectors.

Finishing Options for CNC Machining Parts

Finishes add protection, function or brand appeal. Plan them with your supplier early because some coatings change dimensions or need masking.

- Anodising (Type II / hard anodise): Protection and aesthetics for aluminium; colour-coding made easy.

- Chem film / Alocrom / Iridite: Conductive conversion coating for bonding/EMC.

- Passivation (stainless): Improves corrosion resistance with no dimensional change.

- Electroplating (zinc, nickel, chrome): Protection and conductivity – common on automotive components and electronics.

- Black oxide / phosphate: Low-cost corrosion protection and reduced glare.

- Bead-blast / vibratory tumble: Uniform cosmetic finish and deburring.

- Laser marking: Permanent part IDs, barcodes and traceability.

- Heat treatment: Through-hardening or ageing (e.g., 17-4PH H900, 7075-T6) for strength and wear.

Note: Finishing and heat treatment can shift sizes slightly – coordinate tolerances and masking up front.

Design for Manufacturability (DFM)

Small design choices can remove 10-30% of cost and shorten lead times. Collaborate with your supplier early and use these principles to guide the drawing.

- Generous internal radii (R3–R6) to run larger, faster tools.

- Sensible wall thickness: aim ≥1.0-1.5 mm in aluminium and ≥1.5-2.0 mm in steels to reduce deflection.

- Limit deep, narrow pockets and very small cutters where possible.

- Tight tolerances only where function needs them; relax cosmetic or non-critical features.

- Standard threads and depths with class of fit; confirm if gauges are required.

- Use inserts (helicoils/keyserts) in soft alloys for repeated assembly.

- Clear reference scheme (primary/secondary/tertiary) so machining and CMM agree on measurement.

- Finish notes up front: colours, masking and serialisation.

- Reduce setups: orient features for one or two clamps; apply 5-axis where it truly simplifies access.

- Plan the production bridge: reference schemes, fixtures and inspection plans that scale smoothly.

What Really Drives Price?

Understanding cost drivers helps you compare quotes fairly and identify the best levers when you need to save without risking function.

- Programming & setup time: Significant for prototypes and small batches; amortised at volume.

- Cycle time: Material removal rate, toolpath choice and tool wear; tough materials and micro-features lengthen cycles.

- Tolerances & inspection: Tight limits and complex GD&T slow feeds and expand inspection scope.

- Material & stock form: Alloy price, plate vs bar, and scrap ratio.

- Fixturing & complexity: Thin walls, deep bores and multi-face access need more fixtures or 5-axis.

- Finishing & heat treatment: Extra processing, handling and dimensional compensation.

- Quantity & release plan: Larger batches or call-offs reduce unit cost by spreading setup.

- Lead time pressure: Expedites mean overtime or resequencing.

- Documentation: FAIR/PPAP, CMM reports, serialisation and special packaging add real value and cost.

Fast cost wins: increase non-critical radii and wall thickness, standardise threads, combine operations with mill-turn/5-axis when it truly reduces setups and share a forecast or call-off plan.

How Long Should You Expect to Wait?

Lead times vary with complexity, material and finishing. The ranges below are typical for UK machining and help you plan approvals and assembly dates.

- Rapid prototypes: 3-10 working days

- Pre-production / small batches: 1-3 weeks

- Serial production: scheduled call-offs once the process is proven

Flag special processes early (e.g., hard anodise + engraving + passivation) so they’re built into the schedule.

The Perfect RFQ: What to Include for Fast, Accurate Quotes

A clear RFQ removes ambiguity and speeds up like-for-like pricing. Use this checklist to brief suppliers for CNC machining parts.

Files

3D STEP/Parasolid plus a dimensioned PDF drawing with units, revision and tolerancing standard.

Technical

Material and standard, quantity bands (prototype, pilot, production), any call-off plan, critical GD&T, surface finish/colour and masking, heat treatment, full thread list with depth and class.

Quality & Logistics

Inspection scope (FAIR/ISIR/PPAP), CMM report requirement, material/CoC and traceability, packaging and labelling, target lead time and delivery postcode.

What Great Looks Like in a UK Supplier

The right partner combines capability with communication. Use this list when you’re shortlisting suppliers for CNC machining parts.

- Engineering-led quotations with DFM suggestions

- ISO 9001:2015 quality management and CMM capability

- Breadth of process (milling, turning, 5-axis, mill-turn) and dependable finishing partners

- Repeatability via in-process probing, tool libraries and robust work instructions

- Transparent communication on capacity, lead times and status

- Scalability from prototypes to scheduled production

- Sector fluency matched to your needs – aerospace, medical/scientific, automotive, energy/marine, electronics

FAQs

Quick questions come up on almost every project. This section gives clear, no-nonsense answers so you can move forward faster. (Assume UK sourcing and standards unless stated otherwise.)

Are CNC Machining Parts the Same as Precision Machined Parts?

In everyday use, yes. Both refer to build-to-print components made on CNC mills and lathes.

What Tolerances Should I Start With?

Begin with ±0.05 mm unless function demands tighter. Highlight the few dimensions that truly control fit or performance.

Which File Formats Are Best?

STEP (.stp) or Parasolid (.x_t/.x_b) for 3D, plus a dimensioned PDF drawing. STLs aren’t ideal for machining.

Can Suppliers Handle Finishing and Marking?

Yes – anodising, plating, passivation and laser marking are routine. Include colour codes, masking and serial requirements in your RFQ.

Do UK Shops Support Small Batches?

Absolutely. CNC is well-suited to low-volume, high-variety work. Sharing a forecast or call-off plan helps secure capacity and pricing.

Bringing It All Together (60-Second Checklist)

This quick checklist turns the guidance above into action. Use it before you click “Send RFQ”.

- Share your intent: what the part does, where it lives, expected volumes.

- Keep design friendly: generous radii, sensible walls, standard threads, clear reference faces.

- Put tight tolerances only where needed; state finish and masking up front.

- Send STEP + PDF with quantities and a realistic target date.

- Agree inspection scope (FAIR/PPAP/CMM) before cutting metal.

- Plan the production bridge: from prototype sign-off to call-off deliveries.

The Next Step with Tarvin Precision

If you’d like a second set of eyes on your drawing pack, Tarvin Precision can provide quick DFM feedback and a like-for-like quote from an ISO 9001:2015 and AS9100 UK team. Send a STEP + PDF, quantity bands and any finish/inspection notes and we’ll suggest practical tweaks (where helpful) to shorten lead times or reduce cost – then manufacture to your final spec. When you’re ready, Request a Quote or send a Quick Message, and we’ll take it from there.