Precision engineering UK buying, even for the experienced, is no small task. In the fast-evolving world of advanced manufacturing, the demand for high-quality, custom-made components is greater than ever, so sourcing the right partner is imperative. With factors like low-volume requirements, high variety, and critical tolerances to consider, identifying a capable and reliable supplier can make all the difference in product quality, lead time, and total cost of ownership.

This guide is crafted specifically for seasoned buyers who understand the stakes involved and are looking to align with a supplier that delivers consistent precision, flexible service, and technical competence. Here’s what you need to know when evaluating a precision engineering partner in the UK.

Why Precision Engineering Matters More Than Ever

Precision engineering is at the heart of modern manufacturing, enabling the production of components with exceptionally tight tolerances, intricate geometries, and high-performance materials. Industries such as aerospace, defence, medical, and automotive demand components that not only meet strict dimensional accuracy but also perform reliably in critical environments.

In the UK, the precision engineering sector continues to evolve, with a strong focus on quality assurance, digital integration, and customer-specific solutions. The ability to produce high-quality parts in low volumes while accommodating a wide range of geometries and materials is increasingly valuable. For buyers, this means sourcing from a supplier with a proven track record, technical depth, and the flexibility to handle high-mix, low-volume orders.

What Experienced Buyers Look for in a UK Precision Engineering Supplier

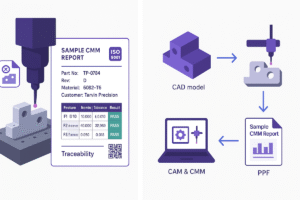

Choosing a precision engineering UK partner is about managing risk and total cost, not just price. Experienced buyers prioritise routine capability with evidence (CMM reports, traceability), reliable lead times, and proactive DFM with clear communication. They also expect suppliers who can switch smoothly from prototypes to repeat orders and back claims with sector-relevant case studies.

Capability and Flexibility

Can the supplier handle a wide range of part types, materials, and finishes? Are they experienced in managing high variety with low batch sizes? Look for companies like Tarvin Precision, which specialise in low-volume, high-variety production, offering tailored solutions for complex and custom parts.

A capable supplier should demonstrate adaptability in switching between projects quickly, handling both prototypes and repeat orders without compromising consistency. Flexibility also means the ability to incorporate design changes mid-production and accommodate a variety of production needs, from R&D samples to finalised assemblies.

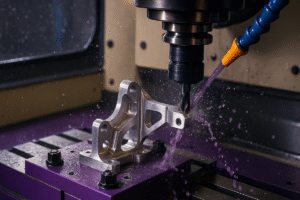

Advanced Machinery

Even for low-volume orders, having access to advanced equipment matters. A precision engineering firm in the UK should operate with modern CNC technology, particularly multi-axis machining, to reduce setups, improve accuracy, and enable more complex geometries.

It’s important to understand how a supplier’s machine shop is configured. Are they investing in automated setups? Do they have modular fixtures or tool libraries that support short turnaround times? The best shops will use their equipment intelligently to maximise value on small batch work.

Quality Systems and Accreditations

ISO 9001 is a minimum requirement. For sectors like aerospace or medical, higher certifications (e.g., AS9100) may be needed. Consistent inspection protocols, in-process quality checks, and traceability systems are signs of a mature operation.

Ask to review their quality manual or a sample inspection report. A robust quality culture will often be reflected in the state of the shop floor: clean, organised, and structured. Look for quality embedded at every stage, from initial quote to final dispatch.

Customer Communication and Engineering Support

The best suppliers don’t just take drawings and deliver parts. They collaborate with you, clarify tolerances, advise on manufacturability, and flag potential design issues. Communication speed and clarity are crucial, particularly for complex parts.

Ideally, the supplier should assign a single point of contact, such as a project engineer, who manages your order from start to finish. Timely updates, proactive consultation, and digital tools (such as shared drawings or tracked revisions) are increasingly expected by experienced buyers.

Track Record and Case Studies

Ask for examples of past work in your industry. A top-tier UK precision engineering company should be able to show successful projects in similar sectors, ideally with testimonials or performance metrics.

Case studies offer insight into how the supplier handles challenges. Did they reduce lead time on a prototype run? Were they able to troubleshoot a manufacturing flaw collaboratively? Firms like Tarvin Precision often develop long-term client relationships precisely because of their ability to deliver under pressure and adapt to evolving project needs.

Common Mistakes Even Experienced Buyers Make

Even those with years of procurement experience can trip on hidden cost drivers – quality drift, schedule risk, and weak process control – not just the £/part line. Use the points below to spot the biggest pitfalls fast and apply simple checks that prevent rework, delays, and admin churn.

Focusing on Unit Price Instead of Total Cost

Chasing the lowest line item looks smart on paper—but in precision engineering UK supply chains, total cost of ownership wins. Rework, scrap, concessions, expedited freight, admin time, and line stoppages can erase any saving from a rock-bottom unit price. A supplier offering £-per-part savings but delivering variable quality, vague documentation, or slips in delivery will cost more once you add the impact on production schedules and customer commitments.

What to look for instead: Predictable quality (first-off approval, in-process checks, final CMM report), clear PPAP/FAIR capability when required, robust packing/traceability, and honest lead-time conversations. Ask for sample inspection reports and references from UK manufacturers with similar tolerance bands and materials. The best precision engineering companies reduce risk, not just price.

Overlooking Supplier Scalability as Demand Shifts

A partner that’s perfect at 50 pieces can struggle at 500 without the right fixtures, programming standards, or capacity planning. When volume spikes, do they have extra spindle hours, lights-out capability, or a qualified sub-tier network for finishing? Can they hold the same tolerances at speed, and how do they prioritise urgent ECOs?

How to de-risk: Verify scheduling discipline (ERP/MRP screenshots are fair to request), setup/changeover approach, and how they maintain capability across multiple machines and shifts. Ask: “What happens if we triple demand for two months?” and “How do you protect form/fit/function during ramp?” In UK precision engineering and subcontract CNC machining, scalability is a quality attribute – it protects delivery, yield and unit economics under real-world pressure.

Not Visiting (or Auditing) the Facility

Brochures don’t show process control. A short on-site (or live video) audit reveals how parts really flow: tool management, gauge calibration, 5S, material segregation, and how non-conformances are handled. Can they walk you through a traveller from goods-in to final pack? Do they run documented first-off approvals and keep CMM programs tied to revision control?

What to check: Clean, organised workstations; labelled fixtures; controlled work instructions; calibration logs; sample CMM reports; batch traceability; secure storage for customer IP; and a clear process for FAIR/ISIR when needed. If travel isn’t feasible, request a live CMM demo on a recent component plus redacted paperwork. Buyers who audit, even briefly, choose precision engineering partners who are proven, not promised.

Assuming “Standard” Lead Times Regardless of Complexity

There’s no such thing as a universal lead time in precision machining. Tolerance stack-ups, material choice (e.g., 316 stainless vs 6082 aluminium), surface finish targets, and external treatments (anodising, passivation, grinding) all move the schedule. Add programming/fixturing, inspection depth (sample vs 100%), and courier cut-offs, and a “standard” promise quickly becomes unreliable.

Smarter approach: Discuss the drawing early. Share batch size, annual usage, critical features, measurement method, and any PPAP/FAIR requirements. Explore blanket orders, call-offs, or VMI to protect production while reducing unit cost. A good UK precision engineering supplier will propose stocking strategies, expedited paths for prototypes, and realistic dates tied to actual capacity – so your plan reflects physics, not optimism.

Top Questions to Ask a UK Precision Engineering Firm

When vetting a potential supplier for precision engineering UK projects, go beyond brochures and slick websites to uncover how they actually control risk, quality, and lead time. A credible partner will evidence metrology discipline, repeatable process control, capacity planning, and sector-specific compliance – not just impressive machine lists. The right questions surface routine tolerances, true multi-axis capability, relevant references, how they protect quality in low volumes, capacity for rapid iterations, and whether they provide proactive DFM to cut total cost.

What tolerances do you routinely work to?

Precision engineering lives and dies on repeatable tolerances, not best-case one-offs. Asking about routine capability reveals the accuracy they hold day-in, day-out across machines, shifts, and batches – not just on a showcase part. Push for typical bands (e.g., ±0.01 mm on prismatic features, tighter on bores/faces when process-capable) and how they verify them (first-off approvals, in-process checks, final CMM with stored programs). A credible UK precision engineering partner will back claims with sample CMM reports, gauge calibration records, and clarity on when they switch processes to achieve tighter limits.

What multi-axis machining capabilities do you have?

Part cost, lead time, and accuracy are all affected by the number of setups. Multi-axis capability (positional or simultaneous) can consolidate operations, improve datum control, and reduce stack-up error – especially on complex geometries and freeform surfaces. This question uncovers envelope limits, workholding/fixture strategies, probing, and whether they can combine milling/turning (e.g., mill-turn with live tooling) to minimise handling. The result: fewer fixtures, tighter features, and more predictable delivery.

Can you provide references in my sector?

Sector experience is a shortcut to risk reduction. Aerospace, defence, medical, motorsport, and energy each carry different compliance, documentation, and cleanliness expectations. References prove they understand your regulators, materials, finishes, and PPAP/FAIR or ISIR rhythms – and that they’ve delivered similar parts under similar scrutiny. Ask for brief, attributable examples (redacted if needed) showing problem → action → measured outcome (yield, OTD, concession rate).

How do you ensure quality for low-volume production?

Prototypes and small batches are where variation hides: frequent changeovers, fresh programs, and new fixtures. Strong suppliers design quality into the first article – tool libraries, controlled CAM posts, documented first-off inspections, and risk-based sampling that ramps to 100% where features are critical. You’re looking for a repeatable inspection workflow (travellers, sign-offs, stored CMM routines) and traceability that scales from 1-off to call-off orders without reinventing the process each time.

What is your capacity for prototyping or rapid iterations?

Early design loops drive total project time more than cycle time ever will. Dedicated prototype capacity (reserved spindle hours, quick-change fixturing, same-day programming) keeps engineering changes moving without derailing production. This question reveals how they schedule fast turns, what lead-time bands look like for 1–10 pieces, and whether they can hold the same tolerances at speed – so your development plan reflects reality, not optimism.

Do you offer design for manufacture (DFM) input?

The best precision engineering companies reduce cost and risk before metal is cut. DFM feedback – on fillet radii, wall thickness, tool access, datum schemes, thread standards, and tolerance allocation – can remove unnecessary secondary ops and make inspection practical. You want proactive, drawing-level guidance with alternatives and quantified impact (e.g., “change to M8 x 1.25 and open this radius to 2 mm to remove a second setup and 15% of cycle time”), not vague comments after the quote.

Emerging Trends in Precision Engineering UK Market

Understanding the broader market can give buyers an edge in negotiation and supplier alignment. If you’re sourcing precision engineering UK services, these trends indicate which suppliers can deliver stable quality, faster lead times, and lower total cost. Use them to shape RFQs, down-select partners, and lock in capability that will still be competitive 12–24 months from now.

Multi-Axis Machining as Standard

More UK firms are investing in multi-axis CNC machines, improving both accuracy and part complexity. This allows for quicker turnaround and fewer setups – especially valuable in low-volume runs. In practice, true 4-/5-axis capability reduces datum transfers, consolidates ops, and tightens tolerance stack-ups, so parts come off the machine closer to print with less hand-finishing. For buyers of precision engineering UK components, that means shorter queues, fewer fixtures to fund, and more predictable CMM results.

What to verify: simultaneous vs. positional 5-axis, mill-turn availability, probing for in-process verification, typical tolerance bands on multi-axis work, and envelope limits vs. your largest parts.

Digitally Driven Workflows

From CAD/CAM integration to real-time job tracking, digital transformation is enhancing transparency and repeatability. Modern UK precision engineering companies connect PDM/PLM to CAM posts, push controlled programs to the shop floor, barcode WIP, and tie CMM routines to drawing revisions. The result is faster ECOs, fewer version errors, and audit-ready traceability. For buyers, a digitally mature partner means clearer schedules, live status updates, and inspection packs that align precisely with the latest revision – cutting admin time and rework risk.

What to verify: revision control from CAD to CMM, operator guidance (digital work instructions), machine monitoring, SPC dashboards, and how you’ll access job status during production.

Reshoring and Supply Chain Resilience

Geopolitical events and logistics disruptions are pushing many firms to prioritise domestic suppliers. UK-based precision engineering offers shorter lead times, easier communication, and stronger IP protection. Reshoring also reduces currency exposure and freight variability, while making on-site audits and first-article approvals simpler. If you’re building a resilient precision engineering UK supply base, look for partners with proven sub-tier finishing networks, call-off or VMI options, and the capacity to flex for spikes without sacrificing tolerance or documentation quality.

What to verify: Lead-time bands by material/finish, expedited paths for prototypes, stocking agreements, and contingency plans for critical spares or repeaters.

Precision Engineering UK vs Overseas Alternatives

Choosing between domestic and offshore machining isn’t just about headline price, it’s about total cost, schedule risk and control. If your parts are tolerance-critical, documentation-heavy, or change frequently, a precision engineering UK partner often delivers better outcomes through faster collaboration, easier audits, and stronger IP protection. Use the points below to compare options on what actually drives value.

Why choose a precision engineering company in the UK?

Working with a UK supplier aligns technical capability with real-time collaboration: same-day calls, quick first-article approvals, and site visits (or live audits) without time-zone lag. That proximity shortens engineering change loops, reduces queue time, and keeps projects moving – especially for low-volume, high-mix work where agility beats a small unit-price saving.

What to verify: RFQ turnaround SLAs, prototype vs. production lead-time bands, capacity signals (spindle hours, shift patterns), and stocking/call-off or VMI options for repeat parts.

Quality and Compliance

UK firms must adhere to rigorous standards and are often more transparent in their processes. You’re buying repeatability and traceability, not just machine hours. Expect documented first-off approvals, in-process checks, calibrated metrology, and CMM reports tied to the current drawing revision – plus FAIR/ISIR or PPAP when required in regulated sectors. This discipline lowers concession risk and speeds audits.

What to verify: Active certifications (e.g., ISO 9001), sample CMM packs, gauge calibration logs, NCR/8D workflow and closure times, and how revision control flows from CAD/CAM to CMM.

Speed and Agility

Proximity reduces lead times and simplifies logistics. Short shipping lanes, aligned courier cut-offs, and no customs delays mean faster prototypes, smoother expedites and more reliable deliveries. For precision engineering UK projects, the ability to adjust mid-batch for ECOs – without resetting the clock – often determines whether a build ships on time.

What to verify: Typical lead-time ranges by material/finish, expedite paths, small-batch capacity (1–10 pcs), and contingency plans for spikes in demand.

Language and Culture

No translation issues or time zone barriers. Nuanced specs – GD&T, surface finish, gauge method, inspection scope – less likely to be misunderstood and daily stand-ups or live screen-shares with CAM/CMM keep intent crystal clear. The cultural fit also helps with proactive DFM suggestions that reduce steps and cost.

What to verify: Named technical contacts, meeting cadence, supported file formats (STEP, Parasolid, native CAD), and how digital work instructions and inspection routines track drawing revisions.

IP and Security

More robust intellectual property protection and safer handling of sensitive designs. UK legal frameworks, NDA enforceability, and UK GDPR expectations create clear obligations for data security, controlled access, and retention policies – vital for defence, medical, or proprietary parts.

What to verify: Secure portals/VPN, role-based access on shop PCs, redaction policies for photos/reports, encrypted backups, and documented data retention/destruction timelines.

While offshore options may seem cheaper on paper, hidden costs often outweigh the benefits – especially in low-volume, high-mix manufacturing where communication and agility are vital. Once you add freight, duties, broker fees, currency swings, higher MOQs, longer ECO cycles, rework logistics, and extra admin time, the “cheapest” quote can become the most expensive. For many buyers, a precision engineering UK partner provides the best value: tighter control, faster iterations, and fewer opportunities for delay or quality drift.

Final Checklist for Vetting Your Supplier

Before committing, use this checklist to ensure you’re selecting the right UK-based precision engineering partner. It’s designed to test real capability, not just brochure claims, across quality evidence, process control, delivery reliability and collaboration. Credible suppliers will always welcome the check.

- Have they demonstrated experience in low-volume, high-variety projects?

- Are their multi-axis machining capabilities aligned with your part complexity?

- Do they have relevant industry certifications (e.g., ISO 9001)?

- Can they provide case studies or client references from your sector?

- Is their quality assurance process robust and transparent?

- Do they offer design for manufacture (DFM) support?

- Are their lead times realistic and reliable?

- Can they accommodate urgent or prototype work without compromising quality?

- Is their communication responsive and clear throughout a project?

- Have you visited the facility (or at least received a virtual tour) to confirm their capabilities?

- Do they have systems in place to scale with your future requirements?

- Are they committed to continuous improvement and investment in equipment or training?

Building Strategic Partnerships Through Precision Engineering

For experienced buyers, the value of a precision engineering partner goes beyond meeting specs – it’s about forging a relationship that enhances the broader supply chain. The right partner contributes insights, offers engineering foresight, and integrates with your workflows to streamline product development and delivery.

Strategic Collaboration Drives Innovation

Involving your engineering supplier early in the development process opens the door to smarter decisions. When a supplier understands your performance goals, budget constraints, and end-use environments, they can provide valuable input on tolerances, materials, and manufacturability. This not only shortens time to market but also reduces costly design revisions and waste.

Firms like Tarvin Precision pride themselves on working closely with clients from concept through to final part delivery. This is particularly vital in industries where component performance is mission-critical, and the cost of failure is high.

The Role of Agility in High-Mix, Low-Volume Production

Agility is often underestimated in supplier evaluation. In high-mix, low-volume manufacturing, projects often shift priorities, require sudden changes to design, or need small-scale prototyping followed by refinement. A good UK precision engineering company is structured to adapt quickly without sacrificing quality or consistency.

By focusing on flexibility, short-run expertise, and fast response times, Tarvin Precision exemplifies this agility—making them a reliable partner for fast-moving sectors like medical technology, defence systems, and custom aerospace assemblies.

Transparent Communication Builds Trust

Seasoned buyers know that issues can arise, especially with complex or novel designs. The differentiator isn’t whether problems happen—it’s how swiftly and clearly they’re communicated and resolved. UK suppliers often offer a cultural and logistical advantage here: fewer misunderstandings, real-time discussions, and easier site visits when needed.

Tarvin Precision places high value on proactive communication, ensuring that clients are never left guessing. Status updates, progress reviews, and direct engineer-to-engineer dialogue are baked into the way they work.

Total Cost of Ownership Perspective

A buyer focused only on unit cost may overlook hidden expenses—rework, delays, quality failures, poor documentation, or supply chain disruption. A supplier that delivers dependable, right-first-time quality helps reduce total cost of ownership (TCO). You save through shorter lead times, fewer engineering changes, and minimal returns.

UK precision engineering firms like Tarvin Precision also minimise overhead with efficient batch transitions, lean setups, and robust quality documentation that eliminates downstream surprises.

UK Precision Engineering

Sourcing the right partner for precision engineering in the UK is about building a long-term relationship that reduce risk, increase efficiency, and support innovation. Whether you’re in aerospace, defence, or medical manufacturing, aligning with a firm like Tarvin Precision, known for its excellence in low-volume, high-variety production, ensures your components meet the highest standards with the flexibility your projects demand.

Choose wisely. The right UK precision engineering partner is a strategic asset, not just a supplier.