Recreating Parts, Restoring Performance

Reverse Engineering

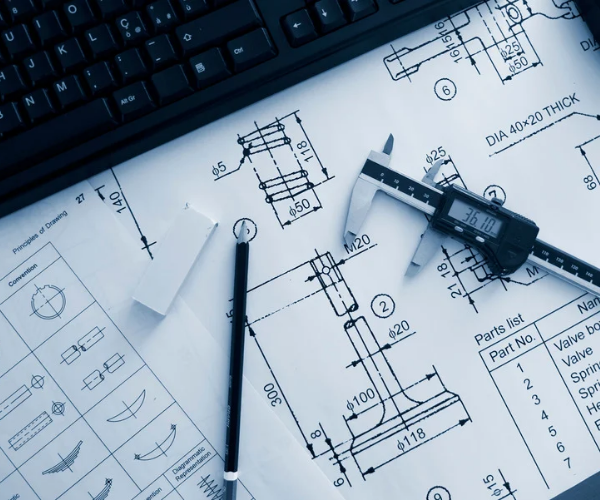

We specialise in reverse engineering components where documentation is lost, supply has lapsed or design needs a second life. From worn parts to legacy assemblies, we turn physical samples into accurate, fully machined replacements.

Reverse Engineering

Whether you’re dealing with a worn, obsolete or unsupported component, we provide a reverse engineering service designed to recreate it.

Our team works from physical samples, partial data or legacy designs to deliver high-accuracy replacements that perform like the original, or better. We support industries where downtime is costly and parts are critical, from legacy vehicles and industrial systems to specialist assemblies and custom machinery.

Our Reverse Engineering Process

We use a combination of hands-on expertise and modern technology to restore or reproduce components accurately. Our process typically includes:

Sample evaluation and dimensional capture

CAD model generation and design verification

Material identification and surface analysis

CNC programming and prototype machining

Test fitting and final production

Whether you need a one-off or a small batch, we deliver components with the same care and quality as a fully spec’d production part.

Common Reverse Engineering Applications

Our reverse engineering capabilities are ideal for:

Legacy automotive and motorsport parts

Discontinued or unsupported OEM components

Damaged or worn items with no available documentation

Adaptations for accessibility, mobility or retrofits

Replacements for supplier shortages or long lead times

We can also incorporate value engineering improvements, material upgrades or design refinements as needed.

Quality and Practicality Combined

All reverse engineering work is delivered under our ISO 9001-certified quality system, with documentation to match. Where appropriate, we apply AS9100-level process control to ensure consistency and traceability – particularly for parts used in regulated sectors.

You benefit from:

Clear, accurate design data created from physical parts

Expert material selection and machining guidance

Quick turnaround and open, technical communication

Full documentation and inspection options available

Why Tarvin for Reverse Engineering?

Reverse engineering isn’t guesswork – it’s a craft backed by decades of machining and problem-solving experience. Tarvin Precision offers:

In-house CAD and engineering support

Skilled machinists and modern CNC capabilities

Flexible volumes from one-offs to repeat batches

A practical, cost-effective approach to difficult parts

Use our online quote form to upload your sample details or CAD file, or send us a message to start the conversation.