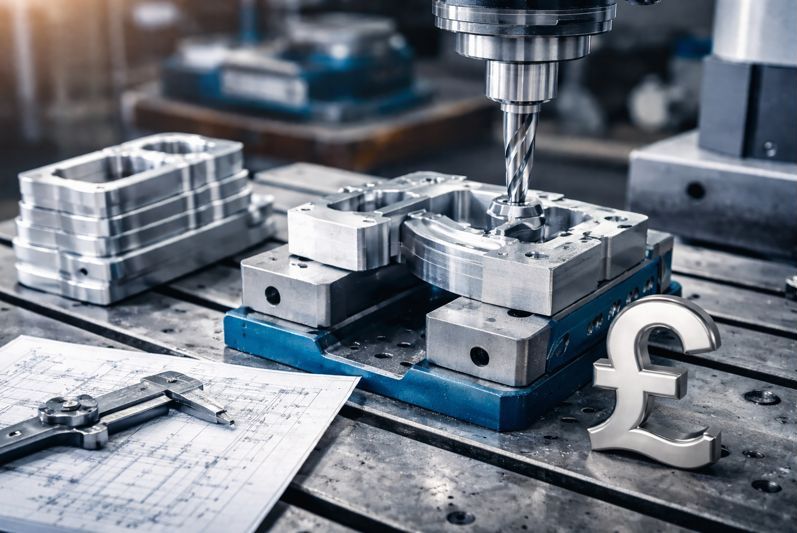

CNC machining costs can feel mysterious because the final price is the sum of lots of small decisions: geometry, material, tolerances, setup time, programming effort, inspection requirements, finishing, and the simple reality of how long the machine is cutting metal (or plastic). The good news is that most of the biggest cost drivers are predictable and, with a little planning, you can often reduce CNC machining costs without compromising function. This guide breaks down how CNC machining costs are built, how to estimate them, and what to change (in design and sourcing) when you need a more competitive quote.

What CNC Machining Costs Really Include (Beyond “Machine Time”)

When people talk about CNC machining costs, they often focus on cycle time – the minutes the tool is cutting. But real-world pricing includes everything needed to reliably deliver conforming parts, on time, with the right documentation. Most quotes blend these cost elements:

- Non-recurring effort (NRE): CAM programming, fixture design, proving-out the job, first-article validation.

- Setup time: loading tools, setting offsets, aligning workholding, running test pieces.

- Run time: actual cutting plus tool changes, probing cycles, chip clearing, and handling.

- Material and waste: billet/plate cost, saw-cut time, and the scrap you can’t avoid.

- Tooling consumption: inserts, end mills, drills, reamers, specialty cutters, and tool wear risk.

- Finishing and secondary ops: deburring, bead blasting, anodising, plating, passivation, painting, heat treatment, grinding, thread inserts.

- Inspection and paperwork: metrology time, CMM programming, FAIR/ISIR/PPAP-style documents (as required), traceability and certs.

- Overhead and risk: scheduling, quality systems, maintenance, utilities, and the probability of scrap or rework on complex features.

Understanding these elements helps you predict CNC machining costs early and makes conversations with a machinist far more productive.

CNC Machining Costs: The Biggest Drivers That Move The Needle

CNC machining costs are dominated by a handful of factors. If you only remember one thing, remember this: complexity and uncertainty cost more than material in many jobs, because they increase setup, programming, and inspection time. Here are the primary drivers you’ll see reflected in quotes:

- Part geometry and feature accessibility (deep pockets, thin walls, undercuts, long reach tooling).

- Tolerances and GD&T (tight limits require stable processes and more inspection).

- Material machinability (titanium and Inconel behave very differently to aluminium).

- Quantity (setup and programming amortise over more parts).

- Surface finish requirements (cosmetic finishes and fine Ra targets add time).

- Datums and inspection scope (more critical features = more measurement time).

- Lead time (expedites can compress scheduling and increase cost).

- Workholding complexity (multiple ops, soft jaws, fixtures, or 4th/5th-axis requirements).

- Process route (turning + milling, 3-axis vs 5-axis, grinding, EDM, etc.).

If you’re trying to reduce CNC machining costs, you’ll get the best results by tackling these drivers before you chase pennies on raw material.

How To Estimate CNC Machining Costs

You don’t need a full costing model to get in the right ballpark. A practical approach is to estimate the main time elements and add material + finishing. Even if you never share the numbers, this helps you sanity-check quotes and spot the real cost levers. A simplified framework looks like this:

- Material cost (including waste)

- Programming & job preparation (NRE)

- Setup time per operation

- Cycle time per part

- Tooling allowance

- Inspection and documentation

- Finishing / secondary operations

- Contingency for complexity and risk

Before you turn that into maths, it helps to define what “one operation” means. An “op” is typically one distinct setup of the part in a machine – each new orientation usually means a new op, new datums, and more time.

With that in mind, a rough costing expression is:

- Total cost ≈ Material + NRE + (Setup hours × shop rate) + (Cycle time × quantity × shop rate) + finishing + inspection

That’s not how every supplier calculates internally, but it’s close enough to help you reason about CNC machining costs and where your quote is coming from.

CNC Machining Costs By Quantity: Prototype vs Low Volume vs Production

CNC machining costs change dramatically with quantity because programming and setup don’t scale linearly. A one-off prototype can look “expensive per part” because the first unit pays for nearly all the preparation.

For a typical precision part:

- Prototype (1–3 pcs): NRE and setup dominate; per-part cost is highest.

- Low volume (10–50 pcs): setup amortises; process stabilises; per-part cost drops fast.

- Mid volume (100–500 pcs): tooling strategy and cycle time optimisation start to matter more.

- High volume (1,000+ pcs): you may outgrow “pure CNC” economics and consider casting/forging + machining, or dedicated fixtures.

If you’re comparing quotes across quantities, ask suppliers to separate one-time costs from unit costs. It’s one of the fastest ways to make CNC machining costs transparent.

CNC Machining Costs By Material (and Why Machinability Matters)

Material selection influences CNC machining costs in two ways: the price of stock and the time/risk to machine it. Two materials can cost similar per kilogram but differ hugely in cutting speed, tool wear, and scrap risk. Common cost tendencies (generalised):

- Aluminium (e.g., 6061/6082): usually low machining time, good tool life, cost-effective.

- Stainless steel (e.g., 303/304/316): slower cutting, more tool wear, higher cycle times.

- Mild steel: can be economical, but finishing and corrosion protection may add cost.

- Titanium: slow, heat-sensitive, higher tool wear; CNC machining costs rise quickly with complexity.

- Nickel alloys (Inconel): very challenging; often high costs and longer lead times.

- Engineering plastics (acetal, PEEK, nylon): can machine quickly, but stability/tolerances may require care.

- Brass: excellent machinability; can be cost-effective despite higher material price.

If you’re in early design, it’s worth asking a machinist whether a more machinable grade (or heat treatment condition) meets your requirements. This is one of the most underused levers to reduce CNC machining costs without redesigning the part.

Tolerances and CNC Machining Costs

Tolerances are one of the most direct multipliers of CNC machining costs. Tight tolerances can require slower feeds, more stable toolpaths, temperature control, additional finishing passes, and more inspection time, especially if the tolerance applies across multiple datums or through multiple setups.

A common cost trap is applying a tight tolerance to an entire drawing when only a few features truly need it. The solution is a functional tolerance strategy:

- Keep tight tolerances only where they affect fit, sealing, alignment, performance, or safety.

- Use standard tolerances elsewhere (or a sensible general tolerance note).

- Define datums that match how the part is actually assembled and measured.

The same applies to surface finish: a fine Ra requirement across non-functional faces can increase machining and polishing time for no functional gain.

Geometry Choices That Increase CNC Machining Costs (Often Unintentionally)

Even strong designs can accidentally force expensive processes. A few geometry decisions consistently inflate CNC machining costs because they reduce tool rigidity, increase ops, or demand special tooling. Examples include:

- Deep narrow pockets that require long, flexible tools (leading to chatter and slower feeds).

- Sharp internal corners that require tiny cutters and long cycle times.

- Thin walls and floors that distort during machining, demanding extra passes and careful workholding.

- Undercuts that need special cutters, EDM, or additional setups.

- Features on many faces that push the job from 3-axis into 4th/5th-axis or multiple setups.

- Tiny threads or deep tapped holes that increase breakage risk and inspection time.

A helpful mental model is: every time you force a longer tool, a smaller tool, or another setup, CNC machining costs rise.

3-axis vs 5-axis CNC Machining Costs: Which is Cheaper?

It’s easy to assume 5-axis is always more expensive. In reality, 5-axis can reduce CNC machining costs when it eliminates multiple setups, complex fixtures, or long-reach tooling. A rule of thumb:

- 3-axis is often cheaper for simple prismatic parts with features on one or two faces.

- 5-axis can be cheaper for complex geometry, features around the part, angled holes, or when you want to machine many faces in one hit.

What matters is the overall process route: fewer setups and better tool access can lower total time and reduce scrap risk, even if the machine hourly rate is higher.

Setup Time, Fixtures and How They Affect CNC Machining Costs

Setup time is the “silent” cost driver, especially in low volumes. It includes aligning the stock, loading tools, setting offsets, proving toolpaths, and validating datums. Complex workholding adds to that, whether it’s soft jaws, custom fixtures, or multiple vices/plates.

If you’re sourcing parts regularly, it’s worth designing with repeatable workholding in mind. Parts that can be located and clamped quickly – and machined in fewer orientations – tend to have lower CNC machining costs and better consistency.

This is also where agile, efficient suppliers can add value. For instance, Tarvin Precision often emphasises an efficient, flexible approach, using value engineering to simplify setups and reduce avoidable operations, without changing the part’s function. Done well, that kind of DFM-driven thinking can cut cost and lead time together.

Cycle Time and Toolpath Strategy

Cycle time is the most visible contributor to CNC machining costs, but it’s also the most misunderstood. It’s not just “how fast the cutter can go.” It’s everything the machine must do to produce a compliant part reliably. Cycle time increases with:

- More tool changes and more tools overall

- Conservative feeds/speeds due to chatter risk

- Finishing passes to hit tolerance or surface finish

- Probing cycles and in-process verification

- Small cutters for tiny radii or fine details

- Clearing chips in deep cavities

- Retracting and re-approaching features

The difference between an average and an optimised toolpath can be significant, especially in harder materials. But optimisation only pays off when quantity is high enough to justify additional CAM effort – another example of how CNC machining costs depend on volume.

Secondary Operations That Surprise People (and Inflate CNC Machining Costs)

Many parts are quoted as “machining + extras.” Those extras are where budgets get blown, particularly when the drawing doesn’t clearly define what’s needed. Common secondary costs include:

- Deburring and edge conditioning (especially on complex parts)

- Thread inserts (Helicoils/Keyserts)

- Heat treatment and post-HT machining

- Anodising/plating/passivation plus masking requirements

- Bead blasting for cosmetic uniformity

- Laser marking and traceability requirements

- Grinding for tight flatness or thickness tolerances

- Assembly, pressing, bonding and torque control

If you want predictable CNC machining costs, call these out explicitly: which edges must be broken, which surfaces are cosmetic, and what masking is required for finishes.

Inspection, Documentation and CNC Machining Costs for Regulated Industries

In aerospace, defence, medical, and other regulated sectors, inspection and documentation can be a major part of CNC machining costs. Requirements like material certs, traceability, CMM reports, first article inspection, and controlled processes add time, but they also reduce risk. If your part doesn’t need that level of paperwork, saying so can reduce cost. Conversely, if it does need it, being specific prevents surprises later. It is important to define:

- Which dimensions are critical to function

- Whether a full CMM report is required or only key features

- Any required standards for documentation and traceability

- Any special process certifications needed for suppliers or subcontractors

A capable shop will price these needs transparently. And when suppliers take a value engineering mindset—again, without being “salesy,” this is something Tarvin Precision is known to do – inspection plans can sometimes be streamlined by clarifying datas and measurement intent, which reduces CNC machining costs while keeping compliance intact.

Lead Time, Scheduling and Why “Expedite” Changes CNC Machining Costs

Lead time affects CNC machining costs because scheduling has a real cost. When you need a job turned around urgently, the shop may need to:

- Interrupt planned work

- Add shifts or overtime

- Reserve capacity and accept opportunity cost

- Compress inspection and finishing queues

- Use faster (sometimes more expensive) material sourcing routes

If you can be flexible on delivery, you often unlock better pricing. Even a small extension (like moving from “ASAP” to “within 2–3 weeks”) can reduce CNC machining costs, especially for complex parts or those needing subcontract finishes.

CNC Machining Costs and Design for Manufacturability (DFM)

If you want the single best way to reduce CNC machining costs, focus on DFM early. A few minutes of design adjustment can eliminate hours of machining, multiple setups, or special tooling.

Before you change anything, think function-first: which features are truly required for performance, safety, and assembly? Then consider these DFM moves:

- Increase internal radii where possible

- Reduce pocket depth-to-width ratios

- Avoid ultra-thin walls unless function demands it

- Consolidate features onto fewer faces

- Use standard drill sizes and thread forms

- Minimise tight tolerances to functional features only

- Add datum features that make inspection straightforward

- Choose materials and finishes that match requirements, not assumptions

This is where collaborative suppliers shine. Efficient, agile machining partners can review a model and suggest small, function-safe changes – classic value engineering – that often reduce CNC machining costs more than negotiating unit price ever will.

Practical Ways to Reduce CNC Machining Costs Without Compromising Performance

Cost reduction works best when it’s targeted. Rather than “make it cheaper,” aim for “remove the expensive uncertainty.” The following tactics are reliable across many projects. Start by prioritising the biggest wins:

- Reduce the number of setups (simplify orientation needs, add sacrificial stock, redesign features).

- Relax non-functional tolerances (especially flatness, position, and surface finish across large areas).

- Avoid tiny tools (increase internal radii and corner relief where possible).

- Standardise holes and threads (common sizes reduce tool changes and risk).

- Specify finishes precisely (masking and cosmetic requirements can be costly).

- Design for straightforward inspection (clear datums and measurable features reduce CMM time).

- Consider quantity breaks (slightly higher order volumes can dramatically reduce unit cost).

If you’re preparing for a design review, these points can guide your questions and help the machinist propose options.

Hidden CNC Machining Costs: What To Look For in Quotes and Drawings

Sometimes CNC machining costs seem high because the supplier is pricing risk. Risk often comes from ambiguity: unclear tolerances, undefined surface finish expectations, or missing details on critical features. Watch for these hidden drivers:

- “General tolerance” notes that imply tighter-than-needed defaults

- Surface finish requirements without specifying where they apply

- Threads without class/fit details where it matters

- Heat treatment requirements without distortion allowances

- No defined datum scheme on parts with positional tolerances

- Tight tolerances across features made in different setups

- Burr-free or “no sharp edges” requirements without defining edge break

A transparent quote typically calls out assumptions. If it doesn’t, ask. Aligning assumptions upfront makes CNC machining costs more predictable and reduces change orders.

CNC Machining Costs for Assemblies

If your component is part of an assembly, the cheapest part isn’t always the cheapest solution. CNC machining costs should be evaluated alongside assembly cost, yield, and field reliability.

For example, a slightly more expensive part that:

- self-locates during assembly,

- reduces fastener count,

- improves alignment, or

- eliminates a manual rework step

…can lower total product cost. This is another area where value engineering can pay off, especially when the machinist understands the assembly context.

FAQ: CNC Machining Costs (Common Questions Buyers Ask)

CNC machining costs depend on specifics, but these answers can help you set expectations and ask better questions.

Why are CNC machining costs so different between suppliers?

Because suppliers have different machine capability, automation level, tooling strategies, scheduling constraints, and risk tolerance. One shop might do a part in two setups; another might need four. The quote reflects the process route as much as the part itself.

Is aluminium always the cheapest?

Often, but not always. Aluminium’s machinability helps, yet if the part requires costly finishing, tight tolerances, or complex workholding, those factors can dominate CNC machining costs.

Do tighter tolerances always mean better quality?

Not automatically. Tight tolerances increase manufacturing effort and inspection time. Better quality comes from appropriate tolerances, stable processes, and clear measurement intent – not just smaller numbers on a drawing.

Can 5-axis reduce CNC machining costs?

Yes, when it eliminates multiple setups, improves tool access, and reduces long-reach machining. It can also improve consistency by keeping more features in one coordinate system.

What should I send for an accurate quote?

A STEP file (or equivalent), a fully toleranced drawing, material specification, finish requirements, quantity, and any inspection/documentation needs. If some items are flexible, state that – flexibility often lowers CNC machining costs.

Making CNC Machining Costs Predictable and Controllable

CNC machining costs are not random; they reflect time, complexity, risk, and requirements. If you want better pricing and fewer surprises, focus on the real drivers: setup count, tolerance strategy, material machinability, inspection scope, and clear finish requirements. The earlier you apply DFM thinking, the more control you have, because changing a model is far cheaper than paying for extra setups or slow toolpaths. Whether you’re sourcing a one-off prototype or a repeat production component, a collaborative approach – where the manufacturer can be efficient, agile, and willing to apply value engineering – often delivers the best outcome for cost, lead time, and reliability.