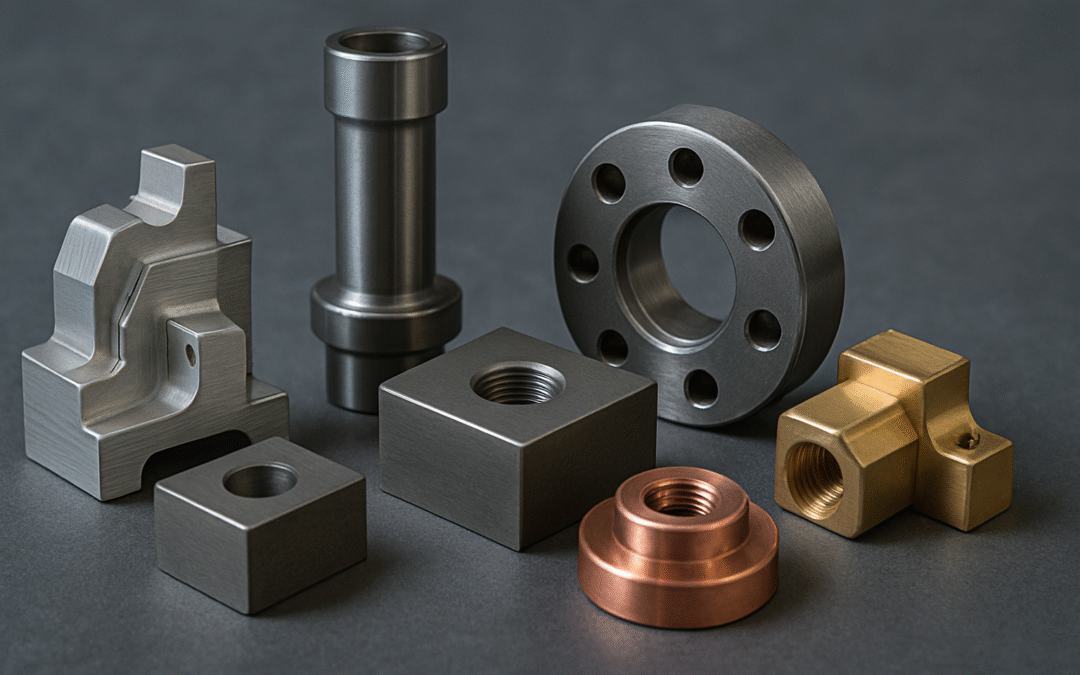

CNC machining services are the foundation of modern precision engineering. From aerospace components to automotive parts and specialist scientific instruments, the process allows manufacturers to produce complex, high-quality parts with exceptional accuracy. Among the many factors that determine the success of a project, material selection stands out as one of the most critical.

While plastics and composites play important roles in some applications, metals remain the dominant choice for industries where strength, durability, and performance are non-negotiable. Each metal brings its own balance of machinability, weight, corrosion resistance, and cost. Choosing the right one requires both technical insight and practical experience.

In the UK, companies like Tarvin Precision provide trusted subcontract CNC machining services across a range of demanding sectors, helping customers make informed decisions and delivering components that meet the highest standards. In this article, we’ll explore the most common metals used in CNC machining – aluminium, stainless steel, mild steel, titanium, Inconel, copper and brass – and look at where they excel.

Why Metals Matter in CNC Machining

Metals are the backbone of CNC machining for good reason. They combine high tensile strength with resilience, conductivity, and thermal performance. This makes them essential in sectors like aerospace, defence, marine, and mining, where components are subjected to extreme conditions.

The choice of metal has direct implications on:

- Durability – Components in aerospace or mining must withstand years of wear, stress, and corrosive environments.

- Precision – Some metals allow tighter tolerances, critical for scientific instruments and defence applications.

- Cost and Efficiency – Machinability determines how quickly and economically parts can be produced.

- Performance – Properties such as weight-to-strength ratio or heat resistance can be decisive in material choice.

Selecting the right metal is therefore not just a technical decision but a strategic one. Working with a precision machining partner such as Tarvin Precision ensures buyers receive both engineering support and accredited quality management throughout the process.

Aluminium

Aluminium is one of the most widely used metals in CNC machining. Its popularity comes from a unique blend of lightweight structure, corrosion resistance, and excellent machinability. CNC machining services often favour aluminium for prototypes and production runs alike because it is cost-effective and highly versatile.

Key properties of aluminium:

- Lightweight yet strong – crucial for aerospace and automotive industries where weight reduction leads to better performance and efficiency.

- Corrosion resistance – protects components in marine, defence, and outdoor applications.

- Machinability – aluminium cuts cleanly, allowing for fine details and smooth finishes.

Applications of aluminium in CNC machining:

- Aerospace brackets, housings, and fittings.

- Automotive components, including lightweight performance parts.

- Scientific instruments requiring corrosion-resistant but precise housings.

- Prototyping, thanks to ease of machining and lower costs compared to exotic alloys.

Stainless Steel

Stainless steel is synonymous with strength and corrosion resistance. It is harder to machine than aluminium but remains a cornerstone of CNC machining services because of its performance in harsh environments.

Key properties of stainless steel:

- Tough and durable – excellent wear resistance for long service life.

- Corrosion-resistant – withstands marine, chemical, and food-grade environments.

- Hygienic – suitable for medical and laboratory applications.

Applications of stainless steel in CNC machining:

- Marine parts exposed to saltwater.

- Defence and aerospace components requiring resilience.

- Surgical tools and medical devices where cleanliness and precision are essential.

- High-strength fixtures and industrial equipment.

Stainless steel requires skilled machinists and advanced equipment to maintain tight tolerances. Precision specialists like Tarvin Precision are well-versed in overcoming these challenges, ensuring components are consistent and reliable.

Mild Steel

Mild steel is a practical and cost-effective material that is widely used in engineering. Though it lacks the corrosion resistance of stainless steel, it offers machinability and affordability that make it attractive for certain applications.

Key properties of mild steel:

- Economical – lower cost compared with stainless steel, titanium, or exotic alloys.

- Versatile – available in many grades, suited to structural and functional parts.

- Machinable – cuts well, allowing efficient CNC production.

Applications of mild steel in CNC machining:

- Fixtures, tooling, and jigs.

- Automotive and industrial components.

- Parts for mining and heavy equipment where robustness is more important than weight savings.

When combined with surface treatments such as plating, coating, or painting, mild steel can achieve good durability for less demanding environments.

Titanium

Titanium is a premium choice in CNC machining services, favoured in sectors where strength, light weight, and corrosion resistance are critical. While titanium is more challenging to machine due to its hardness and tendency to generate heat, its unique benefits justify the investment.

Key properties of titanium:

- High strength-to-weight ratio – stronger than steel but significantly lighter.

- Corrosion resistance – resists seawater, chemicals, and extreme environments.

- Biocompatibility – safe for medical implants and surgical instruments.

Applications of titanium in CNC machining:

- Aerospace parts such as turbine blades, brackets, and airframe components.

- Medical implants and surgical devices.

- Defence systems where performance and reliability are mission-critical.

Machining titanium requires advanced CNC technology, skilled programming, and precise inspection. With 5-axis machining capabilities, advanced UK precision engineering companies can ensure these parts meet the most stringent requirements.

Inconel

Inconel is a family of nickel-chromium-based superalloys renowned for their ability to withstand extreme heat and pressure. Few materials can match its performance in demanding environments, making it essential for industries such as aerospace, defence, and energy.

Key properties of Inconel:

- Heat resistance – maintains strength even at high temperatures.

- Corrosion resistance – ideal for chemically aggressive environments.

- Durability – handles mechanical stress and fatigue better than many alloys.

Applications of Inconel in CNC machining:

- Aerospace turbine blades, exhaust systems, and engine components.

- Marine and subsea equipment exposed to corrosive saltwater.

- Defence components requiring resistance to both heat and stress.

- Mining tools and equipment for high-wear conditions.

Inconel is notoriously difficult to machine, often requiring slower cutting speeds and advanced tooling. Only experienced CNC machining providers can deliver the precision and consistency required for this alloy.

Copper

Copper is valued for its exceptional electrical and thermal conductivity, making it indispensable in industries such as electronics and power generation. While relatively soft compared to other metals, copper’s properties make it a frequent choice in CNC machining services.

Key properties of copper:

- Excellent conductivity – one of the best electrical conductors available.

- Thermal efficiency – widely used in heat transfer applications.

- Machinability – soft and easy to cut, though care is needed to prevent deformation.

Applications of copper in CNC machining:

- Electrical terminals and connectors.

- Heat exchangers and cooling components.

- Bus bars and conductive elements in energy systems.

- Precision parts where conductivity is essential.

Copper’s softness demands careful handling during machining to maintain dimensional accuracy, especially in fine details.

Brass

Brass, an alloy of copper and zinc, combines ease of machining with good mechanical properties and a pleasing finish. It is widely used in precision engineering where both function and appearance matter.

Key properties of brass:

- Easy to machine – produces clean, precise cuts with minimal tool wear.

- Corrosion resistance – holds up well in varied environments.

- Attractive finish – suitable for visible components.

Applications of brass in CNC machining:

- Fittings, valves, and precision connectors.

- Decorative but functional components.

- Instrument parts requiring both durability and visual appeal.

- Low-friction components in engineering systems.

Brass offers an excellent balance of machinability, performance, and aesthetics, making it a favourite across sectors from instrumentation to automotive.

Machining Challenges and How They’re Overcome

While each metal offers unique advantages, they also bring their own machining challenges. Understanding and overcoming these issues is part of what makes CNC machining services so valuable.

Aluminium

Highly machinable, but softer grades can suffer from burrs if not handled correctly. Skilled programming and sharp tooling ensure clean, accurate parts.

Stainless steel

Hardens quickly during machining, which can lead to tool wear and heat build-up. Precision CNC techniques, coolant strategies, and careful feeds and speeds allow consistent quality.

Mild steel

Easy to machine, but it can rust quickly without surface protection. Many components are finished with coatings or plating to extend their lifespan.

Titanium

Notoriously difficult to machine because of its strength and heat resistance. Advanced 5-axis machining centres, toolpath optimisation, and rigid setups are essential for precision results.

Inconel

One of the toughest alloys to work with, as it resists cutting and generates extreme heat. CNC specialists use slower machining speeds, high-performance tooling, and in-process inspection to maintain accuracy.

Copper

Machines easily but is prone to distortion due to its softness. Precision setups and fixturing help maintain tolerances.

Brass

Straightforward to machine but requires careful control to achieve consistent finishes, especially for decorative or visible components.

These challenges highlight why material knowledge is just as important as machining capability. By combining experience, advanced equipment, and rigorous inspection, companies precision engineering in the UK can consistently delivers components that perform exactly as intended, regardless of the metal or its complexity.

Choosing the Right Metal for Your Project

The decision between aluminium, stainless steel, mild steel, titanium, Inconel, copper, or brass depends on balancing performance, environment, and budget. Aerospace and medical sectors might prioritise titanium for its strength and biocompatibility, while marine applications demand stainless steel or Inconel for corrosion resistance. Automotive and general engineering often rely on aluminium or mild steel for cost-effective performance.

Selecting the right material is easier with expert guidance. With over 30 years of experience and AS9100 accreditation, Tarvin Precision supports customers not only with advanced CNC machining services but also with engineering advice to ensure the best outcomes.

Metals and CNC Machining Services

Metals are the foundation of CNC machining services, enabling the creation of durable, precise, and high-performance components. Whether it’s aluminium for lightweight aerospace structures, stainless steel for marine equipment, mild steel for cost-effective fixtures, titanium for cutting-edge medical parts, Inconel for high-temperature aerospace applications, copper for conductive systems, or brass for precision fittings, each material plays a vital role.

Ultimately, success depends on pairing the right material with the right machining partner. Tarvin Precision combines advanced CNC technology, strict quality systems and decades of expertise to deliver results that meet the highest standards across industries.

If you’re looking for a reliable partner for CNC machining services in aluminium, stainless steel, mild steel, titanium, Inconel, copper or brass, contact Tarvin Precision today to discuss your project. Send us a quick message or request a quote.